In the end, the traditional pyramids we are used to seeing in supply chain management and logistics are poised to be disrupted. While we aren’t entirely in that stage yet and most organizations have started to explore the possibilities of smart logistics and supply chain management, others are taking the lead or forced to move faster to meet the demands of the stakeholders in their ecosystems (including internal stakeholders).

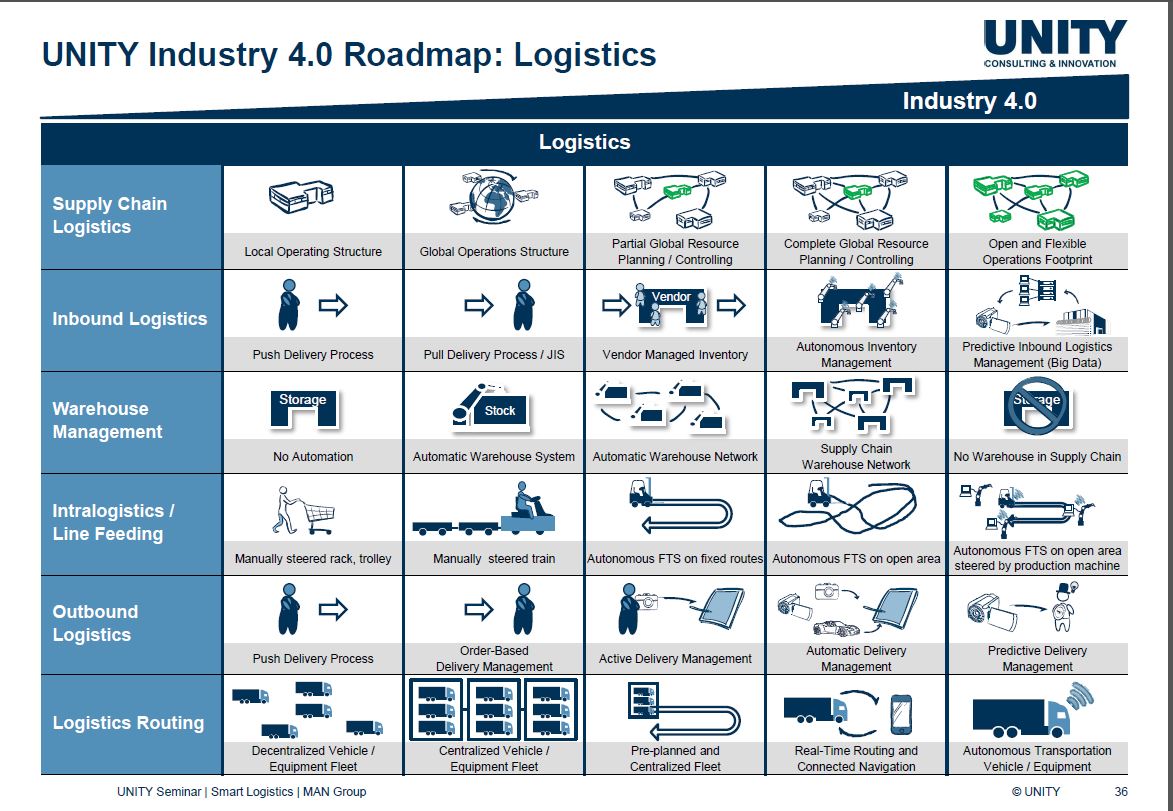

The road ahead is one of more autonomy across various logistics components such as supply chain logistics, inbound logistics, warehouse management, intralogistics or line feeding, outbound logistics, and logistics routing. One of the best images depicting the evolutions towards more autonomy across all these areas is the roadmap image from UNITY Consulting and Innovation which you see below. In that roadmap, a highly autonomous, flexible, and predictive picture is painted in later stages, even until there is no more warehouse in the supply chain.

The technologies and value in connected logistics and the digital supply chain: SCM, flexibility, speed, and quality

With regards to the future stages as shown in the image, before we would ever get there quite some challenges arise, and changes are needed and the macro-economic context would have to seriously change (leaving aside regulations regarding security, the digital economy, and the organization of work).

Today everyone most people have heard – or even deploys or tested – one or more of the several applications which have been known for years: autonomous vehicles, swarm intelligence, AVGs, and trucks, smart shelves that organize their replenishment, smart containers that organize their supply chains, bins and so forth.

Yet, as per usual it’s not just about the technologies, even if newer technologies keep being added, for instance on the level of interfaces, blockchain, new advancements in AI and machine learning, better drones in logistics, cobots, and the list goes on.

It’s about the way logistics and supply chain management meet the needs of all stakeholders, knowing that flexible, smart supply chain decisions, enabled by the human, organizational and technological components of Industry 4.0 and logistics 4.0 make the difference in gaining competitive benefits but also in surviving in a hyper-connected age where the need for speed is high and regardless of the supply chain, performance and speed are crucial but so is quality.

To put it simply: having a smart container is one thing, being able to track what’s inside it, where it comes from and in what state it is, that’s when you start reaping the benefits of a strategic and holistic approach that looks at the value and customer demand.

Intelligent Supply Chain Management: Why You Need It and How to Get There

Digital transformation continues to impact nearly every branch of every industry – from large-scale production and transportation down to individual customer service and eCommerce. Customer Packaged Goods (CPG), retail, and manufacturing have seen some of the largest transformations through advances in digital technology. There is a multitude of process areas we can examine to learn how to best reap the benefits of digital transformation. For now, let’s focus on one – supply chain management.

Intelligent supply chain management calls for the implementation and leveraging of modern technologies to optimize various facets of the supply chain. With an intelligent supply chain, companies leverage modern technologies to collect data and develop insights to better optimize their supply chain. This can save on costs, increase profitability, increase their speed to customers, and get ahead of their competition.

What Does Intelligent Supply Chain Management Look Like?

Intelligent supply chain management is possible when businesses take full advantage of the latest retail digital transformation technologies – artificial intelligence (AI), machine learning (ML), predictive analytics, unified commerce, and big data.

Artificial intelligence, which encompasses machine learning and predictive analytics, is helping to power supply chain business intelligence. These technology solutions utilize big data, logistics patterns, and business trends to inform and optimize the entire digital supply chain. While aspects of the supply chain historically were manual and imperfect, intelligent supply chain management is greatly improving accuracy and visibility.

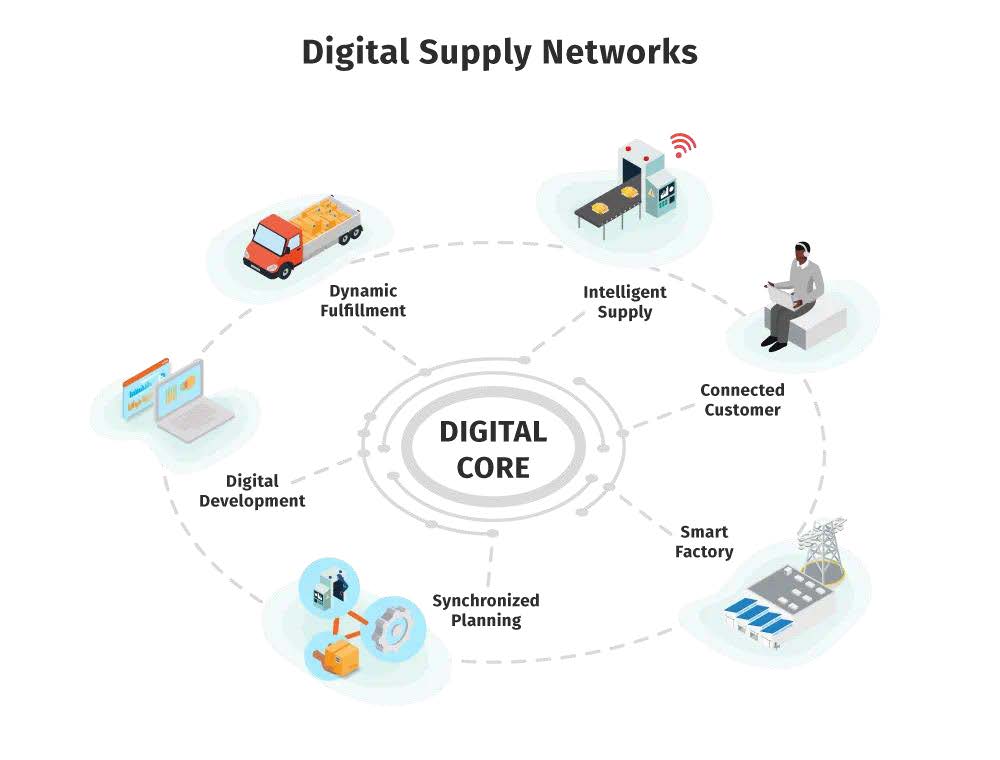

So, what does this all mean? Intelligent supply chain management means that the supply chain is no longer an independent entity of retail or manufacturing companies. Today, all areas of operation — your supply chain included — should be integrated and optimized using connected networks and troves of data to vastly improve forecasting, decision-making, cost control, and overall efficiency.

You Should Also Read:

Logistics 4.0 and Smart Supply Chain Management

Supply Chain Certification’s Value in Your Resume

Role of Cyber Security in Supply Chain Risk Management

Danish Mairaj is a medical device expert with a strong focus on regulatory and quality compliance. He has been involved in managing clinical trial infrastructure including supplies and logistics. He has over 15 years of experience in the MedTech and Pharmaceutical industry. He is a certified Product Owner, Scrum Master, and Project Management Professional PMP. He studied Biomedical Engineering in Germany and MedTech Regulatory & Quality in Galway, Ireland. He contributes articles to the BRASI newsletter.

- Danish Mairaj#molongui-disabled-link