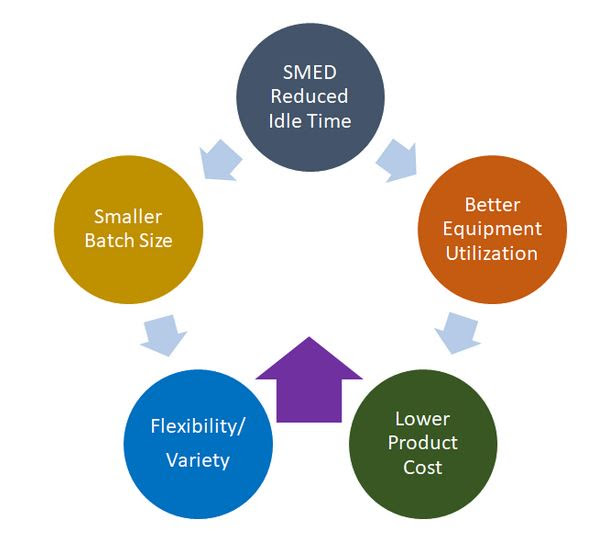

SMED – or Single Minute Exchange of Dies approach aims at reducing changeover time from one process set up to another, in order to switch the equipment from making one product to another. While necessary, the set-up time is non-productive time or downtime when the equipment is not producing any product, but standing idle as it is being set up. This reduces the overall productivity of the equipment and adds cost to the product. Therefore, efforts are made to minimize the setup time, hence the phrase, “Single Minute Exchange of Dies”. Several methods and tools are utilized to minimize set-up times.

Longer setup time also requires that larger production batches be made within one set-up in order to spread the setup cost over a large number of units produced, hence lowering the cost. This reduces the flexibility of switching between products quickly, potentially impacting customer service.

Just like many productivity improvement approaches, SMED can be applied to any situation where a set is needed in order to change between products or programs, for example, transports fleets, convention halls, sports facilities, etc.

Related: SAP The Importance of Real-time Data

SMED is a topic within Lean, which is discussed along with other productivity improvement tools in Module 4 of CISCOM.

Contributed by:

Aftab Khan, CISCOM

Aftab Khan is a logistics specialist with over forty years of experience in all aspects of supply chain and logistics management. He is an engineer by training and holds an MBA, besides several certifications from APICS/ASCM, ISCEA, and BRASI. Mr. Khan is the Executive Director of Business Research and Service Institute LLC, USA.