The supply chain of electric vehicles (EV) and gasoline fuel vehicles (GFV) are significantly different, primarily due to the differences in their power sources.

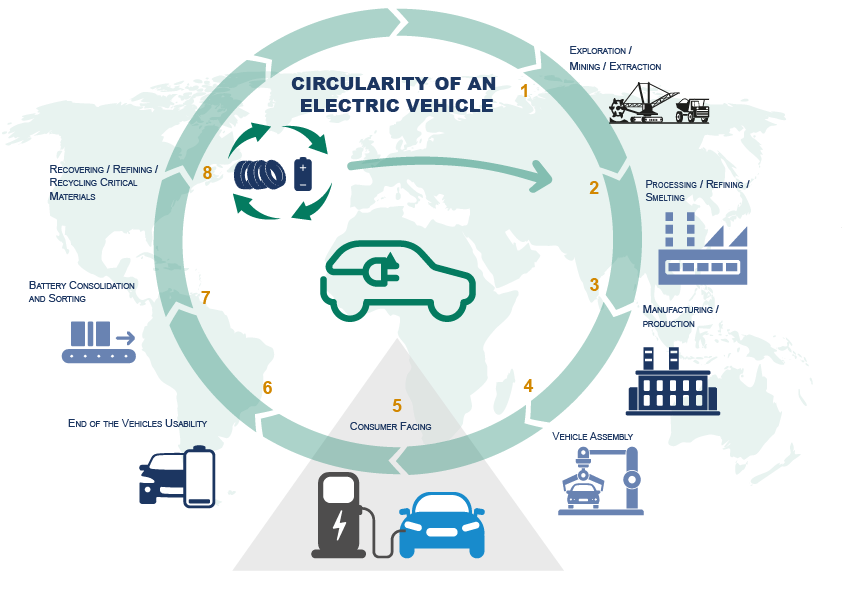

The supply chain of an electric vehicle includes:

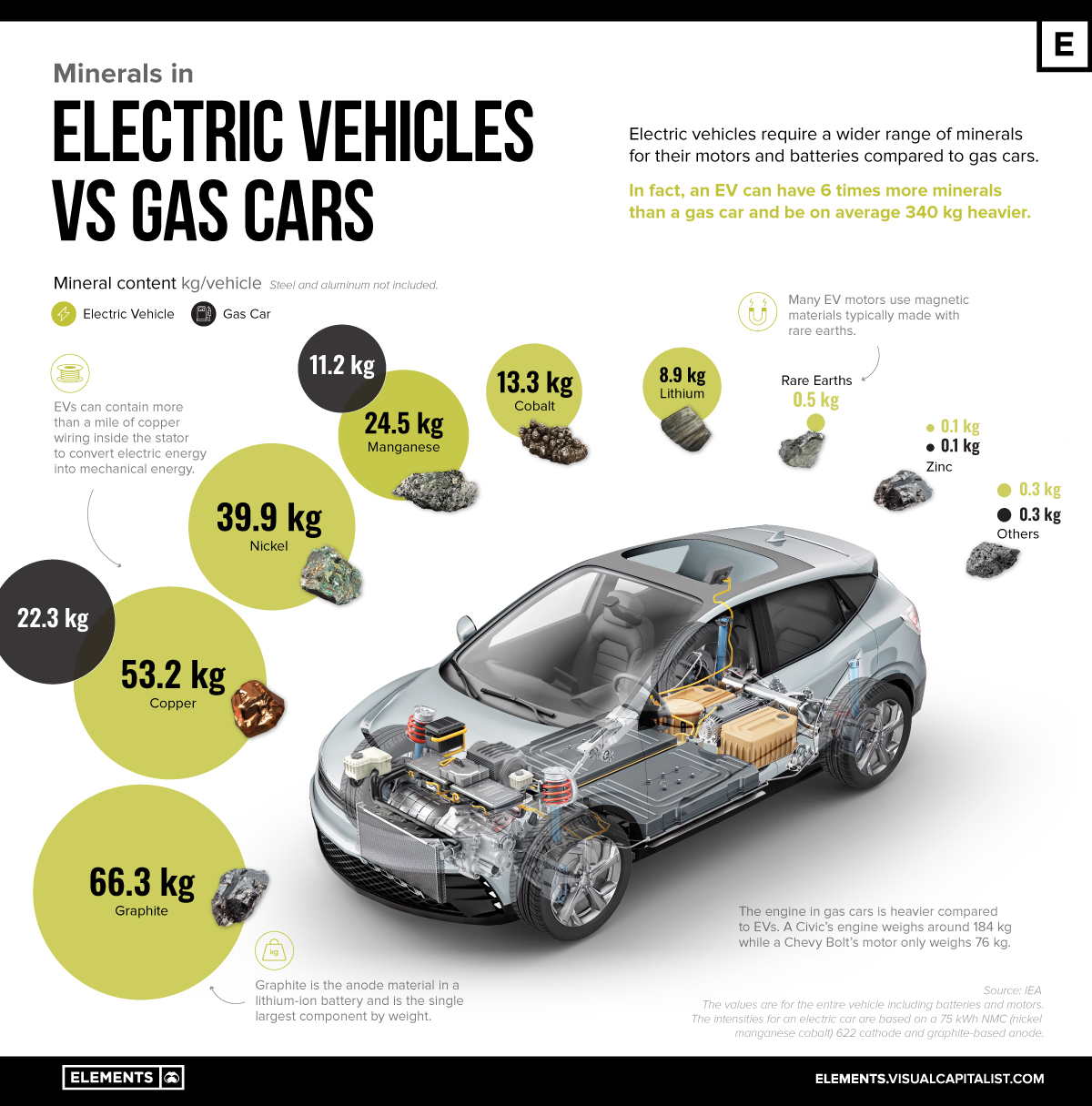

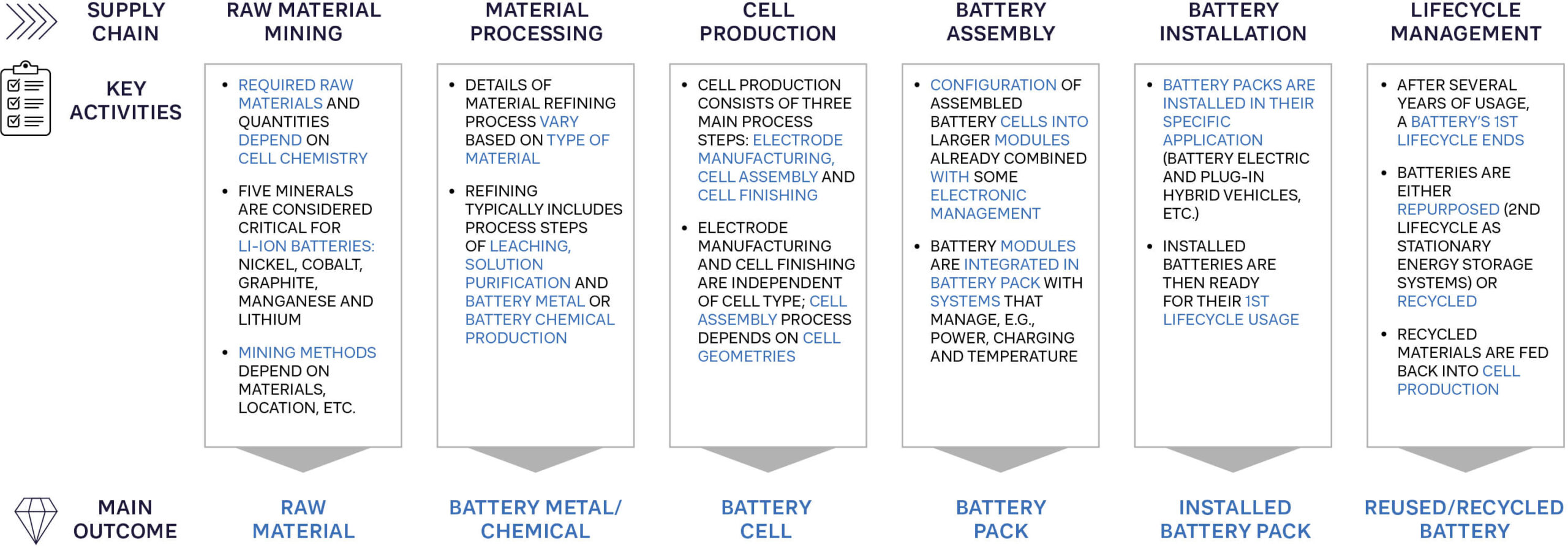

- Raw materials: The raw materials used in EVs include lithium, cobalt, nickel, and graphite, among others. These materials are mined and processed in various locations worldwide.

- Battery manufacturing: The manufacturing of EV batteries involves assembling the cells, which are then packed into modules and integrated into the battery pack.

- Electric motor manufacturing: The electric motor is responsible for converting the electrical energy stored in the battery into mechanical energy to drive the vehicle. The manufacturing of the electric motor involves sourcing the materials, assembly, and testing.

- Assembly of the vehicle: The assembly of the EV involves the integration of the battery, electric motor, and other components into the vehicle.

- Charging infrastructure: EVs require charging infrastructure to recharge their batteries. The infrastructure includes charging stations and cables.

Related: What is Strategic Sourcing in Supply Chain Management?

On the other hand, the supply chain of a gasoline fuel vehicle includes:

- Raw materials: The raw materials used in GFVs include crude oil, which is sourced from oil wells in various locations worldwide.

- Refining: Crude oil is refined to produce gasoline, diesel, and other fuels.

- Engine manufacturing: The internal combustion engine is responsible for converting the fuel into mechanical energy to drive the vehicle. The engine is manufactured by sourcing materials, assembling, and testing.

- Assembly of the vehicle: The assembly of the GFV involves integrating the engine and other components into the vehicle.

- Fueling infrastructure: GFVs require fueling infrastructure such as gas stations to refill their tanks.

Related: Emerging Trends in Supply Chain Management

Overall, the supply chain of an EV is more complex and includes more steps compared to a GFV due to the production and integration of the battery and electric motor. However, the supply chain of a GFV is more dependent on the extraction and refining of crude oil, which can have significant environmental impacts

References:

https://www.erm.com/insights/building-the-connected-ev-circularity-collaboration-competitiveness/

https://elements.visualcapitalist.com/evs-vs-gas-vehicles-what-are-cars-made-out-of/

Aftab Khan is a logistics specialist with over forty years of experience in all aspects of supply chain and logistics management. He is an engineer by training and holds an MBA, besides several certifications from APICS/ASCM, ISCEA, and BRASI. Mr. Khan is the Executive Director of Business Research and Service Institute LLC, USA.

-

Aftab Khan#molongui-disabled-link