Are you looking for ways to make your supply chain more efficient? Have you ever thought about how to cut storage costs and reduce delivery time? If that’s the case, then cross docking might be the solution you are looking for.

Cross-docking is a logistics strategy that minimizes the time spent stored at facilities and quickens the inbound and outbound product flow. Imagine the possibility of “docking and going.” But what does this mean, and why is it important to you? Let’s dive into everything you need to know about cross-docking.

What is Cross Docking?

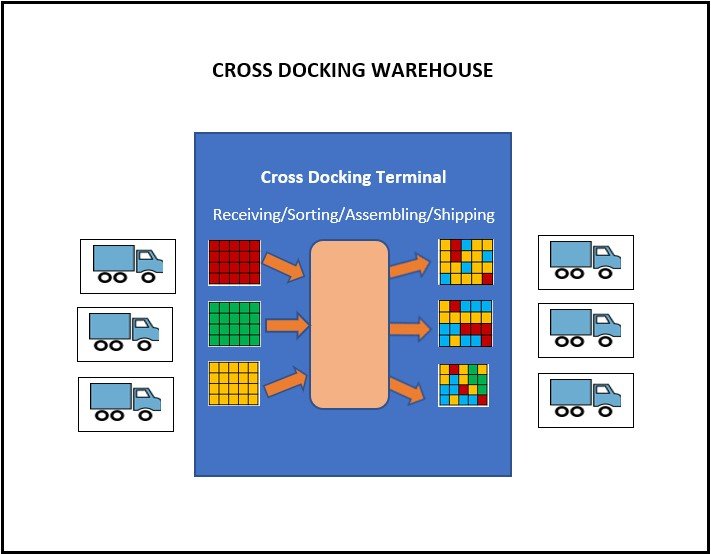

Cross-docking is a supply chain strategy designed to eliminate unnecessary storage and keep goods moving efficiently. Instead of sending products to a warehouse for long-term storage, cross-docking allows them to be transferred directly from inbound to outbound transportation.

How It Works

- Inbound Delivery: Products arrive at a distribution center or cross-docking facility.

- Sorting & Allocation: Goods are sorted and grouped based on their final destination.

- Outbound Shipment: Products are quickly loaded onto outgoing trucks for immediate delivery.

Think of it as a quick airport transfer passengers (products) don’t need to leave the gate area; they simply move from one flight (truck) to another.

Why Cross Docking Matters

- Reduces storage costs by minimizing warehouse usage.

- Speeds up delivery times for faster customer fulfillment.

- Reduces handling risks by minimizing touchpoints and damage.

- Improves supply chain efficiency by streamlining inventory flow.

Cross-docking is a “just-in-time” logistics approach, ensuring that products move quickly through the supply chain while reducing overhead costs.

Different Types of Cross Docking: Finding the Right Fit for Your Business

Just like you wouldn’t wear a heavy coat in the summer, cross-docking comes in different “styles” to suit different needs. Let’s explore the various types to see which one might be the perfect fit for your business.

1. Pre-Distributed Cross Docking (Supplier-Prepared)

In this approach, the suppliers do all the heavy lifting before the goods even reach the cross-docking facility. They organize, sort, and label everything, so it’s ready for a quick transfer.

This method works great for businesses with predictable demand and a reliable supplier network. It cuts down the time spent at the dock, making the whole process faster and more efficient.

2. Opportunistic (Flexible) Cross Docking

Here, goods arrive at the facility unsorted and are then organized based on real-time demand or last-minute changes. This is ideal for businesses that need the flexibility to adapt quickly to shifts in customer demand. It gives you the freedom to adjust distribution plans at the last moment, ensuring you’re always prepared, no matter what the market throws at you.

3. Continuous (Non-Stop) Cross Docking

As the name suggests, this method is all about constant movement. Goods are in a perpetual state of transit, flowing seamlessly from one truck to another. It’s perfect for businesses with high-volume products that need to keep moving, such as grocery stores or large retailers. With non-stop cross-docking, there’s no room for delays or downtime.

4. Consolidation (Batch) Cross Docking

This involves consolidating smaller shipments from multiple suppliers into one big shipment. It helps maximize the use of space in outbound trucks, reducing transportation costs. If your business deals with small batches of goods from various sources, batch cross-docking can help streamline your logistics process.

5. Deconsolidation (Break-Bulk) Cross Docking

Think of this method as the reverse of batch cross-docking. Instead of combining shipments, you’re breaking down a large shipment into smaller ones for different destinations. It’s often used in e-commerce or retail when goods need to be distributed to multiple locations quickly and efficiently.

When Should Cross Docking Be Used?

Not every business needs to use cross-docking. It’s most effective in certain situations:

- Perishable Goods: If you’re dealing with items that have a short shelf life, like pharmaceuticals, fruits or dairy products, cross-docking helps move them quickly to avoid spoilage.

- High Turnover Retail Items: Products that sell fast, like electronics or seasonal goods, benefit from cross-docking. It ensures shelves stay stocked without overloading warehouses.

- Emergency Shipments: When time is of the essence, such as during a disaster relief effort or urgent medical supplies, cross-docking speeds up the process.

So, should your business consider cross-docking? If speed and efficiency are your top priorities, it might be worth looking into.

Cross Docking vs. Traditional Warehousing

Now, you might be thinking, “How is cross-docking different from traditional warehousing?” Let’s break it down:

Definition and Purpose

- Cross Docking: Focuses on moving products quickly from arrival to departure with minimal storage.

- Warehousing: Involves storing goods for an extended period before they are shipped out.

Key Differences

- Storage Time: Cross-docking minimizes storage, while warehousing relies on it.

- Handling Requirements: Cross-docking involves less handling, reducing the risk of damage. Warehousing may involve multiple handling stages.

- Cost Implications: Cross-docking often results in lower storage costs, while warehousing might incur higher costs due to long-term storage needs.

Pros and Cons of Each Approach

| Feature | Cross-Docking | Warehousing |

| Storage Time | Minimal to none | Longer duration |

| Handling Requirements | Minimal (less risk of damage) | Multiple handling stages |

| Cost | Reduced storage costs | Higher due to storage expenses |

| Flexibility | Less flexibility for sudden storage needs | Greater flexibility for storing unexpected inventory |

Primary Advantages of Cross Docking

So, why do businesses choose cross docking? Let’s explore some key benefits:

Key Benefits

- Reduced Storage Costs: Less time in storage means lower costs. Businesses save on warehousing fees, inventory holding costs, and even on utilities.

- Faster Shipping Times: With products moving swiftly from one truck to another, shipping times are cut down dramatically. This leads to faster deliveries and happier customers.

- Minimized Handling: With fewer steps between arrival and departure, the chances of damage decrease significantly. Less handling means less wear and tear on products.

- Improved Inventory Management: Cross-docking helps maintain a lean inventory. You only stock what’s necessary, reducing waste and optimizing storage space.

Real-Life Example

Consider Walmart, a giant in the retail world. Walmart uses cross-docking to streamline its supply chain. By moving products quickly from supplier trucks to store delivery trucks, they keep shelves stocked efficiently without overburdening their warehouses.

Risks and Challenges of Cross Docking

Of course, cross-docking isn’t without its risks. Here are a few to keep in mind:

- Initial Setup Costs: Establishing a cross-docking facility requires an upfront investment in infrastructure and technology.

- Dependency on Reliable Suppliers: Cross-docking relies on precise timing. A delay from one supplier can disrupt the entire process.

- Requires Advanced Inventory Management Systems: To succeed, cross-docking needs advanced systems that track and coordinate goods in real time.

Why Businesses Choose Cross Docking

Despite these challenges, many businesses opt for cross-docking. Why?

Because the benefits outweigh the risks. Companies want faster delivery times, reduced costs, and better inventory management. In a competitive market, these advantages can make all the difference.

Industries That Use Cross Docking

Cross-docking isn’t just for big retailers. Many industries use this strategy to streamline their operations:

- Retail: Stores like Walmart and Target use cross-docking to keep their shelves stocked without overfilling warehouses.

- E-commerce: Online businesses use cross-docking to handle high volumes of orders and ensure quick delivery.

- Automotive: Car manufacturers use it to get parts to assembly lines faster.

- Pharmaceuticals: Drug companies use cross-docking to maintain the freshness and quality of their products.

Cross Dock Warehouses: What You Need to Know

So, what does a cross-dock warehouse look like? Here are a few key features:

- Minimal Storage Space: Unlike traditional warehouses, cross-dock facilities have little to no storage space. They are designed for fast unloading and loading.

- Open Floor Plans: To facilitate easy movement of goods, these warehouses often have wide, open floor plans.

- Efficient Docking Stations: Multiple docking stations allow for quick transfers from inbound to outbound trucks.

Is Cross Docking Right for Your Business?

Before implementing cross-docking, assess your business needs:

- Product Type: Perishable and high-demand items are ideal candidates.

- Supplier Reliability: Ensure your suppliers can meet strict delivery schedules.

- Volume of Goods: High-volume operations benefit the most from cross-docking efficiencies.

By carefully evaluating these factors, you can determine if cross-docking aligns with your operational goals and can enhance your supply chain efficiency.

Conclusion

Cross-docking is more than just a trend; it’s a powerful strategy that can help businesses improve their supply chain efficiency. Whether you operate in retail, e-commerce, or healthcare, this method can help reduce costs, speed up deliveries, and optimize inventory flow.

For businesses looking to deepen their understanding of such advanced techniques, the CISCOM (Certified in Supply Chain & Operations Management) course offers comprehensive training in supply chain management, including cross docking, Lean, and Six Sigma methodologies. Investing in supply chain education can help future proof your business and keep you ahead of the competition.

Aftab Khan is a logistics specialist with over forty years of experience in all aspects of supply chain and logistics management. He is an engineer by training and holds an MBA, besides several certifications from APICS/ASCM, ISCEA, and BRASI. Mr. Khan is the Executive Director of Business Research and Service Institute LLC, USA.

One Response

thanks for this article about cross docking and multiple advantage for use this strategy