Efficiency, defect reduction, and customer satisfaction are paramount in today’s competitive business landscape.

Organizations continuously seek methods to improve their operations and meet customer demands.

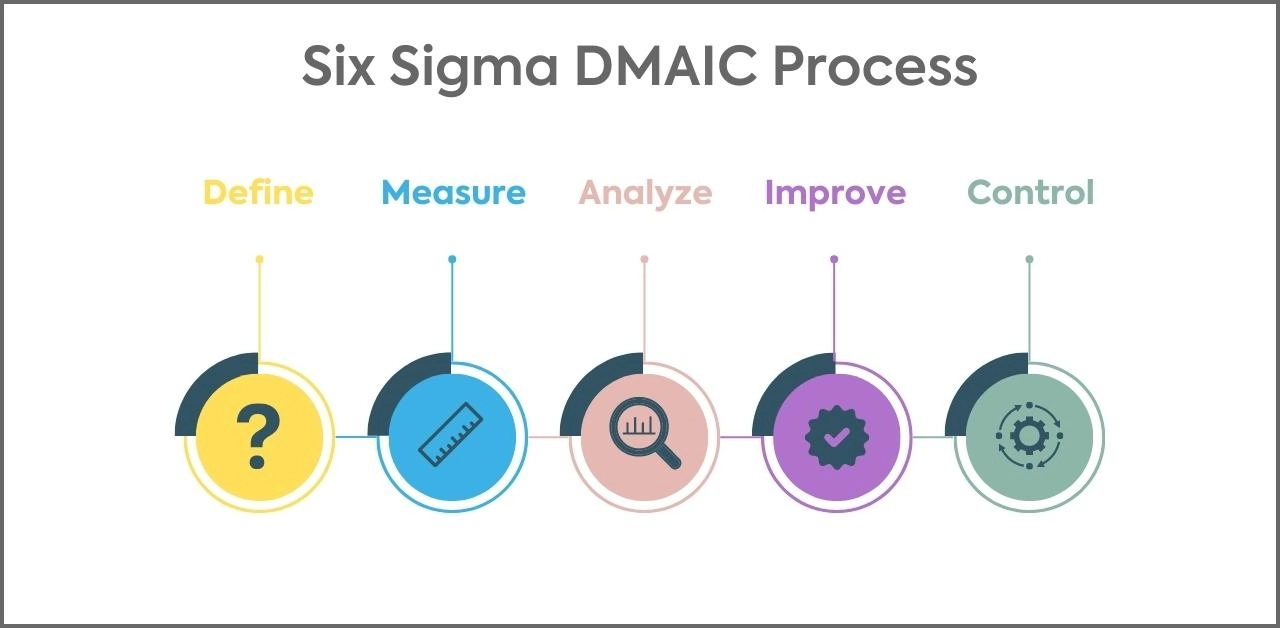

One highly effective approach that has gained significant popularity in achieving these goals is the Six Sigma DMAIC process.

In this article, we will go into detail about the Six Sigma DMAIC process and how it can significantly enhance business efficiency.

What is the Six Sigma DMAIC Process?

The Six Sigma DMAIC (Define, Measure, Analyze, Improve, and Control) process is a structured problem-solving approach that provides organizations with a systematic framework to identify and eliminate process defects, reduce variations, and optimize performance.

By following the DMAIC process, businesses can achieve significant improvements in quality, efficiency, and customer satisfaction.

1. Define Phase

Project Identification

In the Define phase of the Six Sigma DMAIC process, the first step is to identify a project that aligns with the organization’s goals and objectives. This involves selecting a problem or opportunity that can benefit from the application of the DMAIC process.

Project Scope

Once the project is identified, the next step in the Define phase is to clearly define its scope. This includes setting specific goals, establishing boundaries, and identifying key stakeholders involved in the process.

Voice of the Customer

Understanding the customer’s needs and expectations is crucial for the success of any improvement initiative. During the Define phase, gathering the Voice of the Customer (VOC) through surveys, interviews, and data analysis helps determine the critical requirements and prioritize improvement efforts.

Process Mapping

Process mapping, a critical activity in the Define phase, involves visually representing the current process flow, including inputs, outputs, and key process steps. This helps identify bottlenecks, redundancies, and areas for improvement.

2. Measure Phase

Data Collection

In the Measure phase, relevant data is collected to evaluate the current performance of the process. This may involve sampling, observations, or data extraction from existing systems. Accurate and comprehensive data collection is essential for making informed decisions.

Data Analysis

Once the data is collected, it is analyzed to identify patterns, trends, and areas of improvement. Statistical tools and techniques are utilized to gain insights into the process performance and to determine the root causes of defects or variations.

Performance Metrics

Performance metrics are established to measure the effectiveness and efficiency of the process. Key performance indicators (KPIs) are defined, which serve as benchmarks for tracking progress and evaluating the success of improvement initiatives.

3. Analyze Phase

Root Cause Analysis

The Analyze phase focuses on identifying the root causes of process defects or variations. Techniques like cause-and-effect diagrams, 5 Whys, and fishbone diagrams are used to systematically analyze the data and uncover the underlying causes of the identified issues.

Process Variation

Understanding process variation is critical to improving efficiency and reducing defects. Statistical analysis techniques such as control charts and process capability studies help assess the extent of process variation and determine if the process is stable and capable of meeting customer requirements.

Hypothesis Testing

Hypothesis testing is employed to validate assumptions and determine the statistical significance of potential solutions. It helps make data-driven decisions and identify the most effective improvement strategies.

Pareto Analysis

Pareto analysis is a technique used to prioritize improvement opportunities. It identifies the vital few factors that contribute to the majority of defects or issues, enabling organizations to focus their efforts and resources on the most significant areas for improvement.

4. Improve Phase

Solution Development

In the Improve phase, potential solutions are developed based on the findings from the previous phases. These solutions aim to address the identified root causes and improve the overall process performance. Brainstorming sessions, design of experiments, and best practice research are commonly used to generate innovative solutions.

Solution Implementation

Once the solutions are developed, they are implemented in a controlled manner. Pilot testing may be conducted to assess the effectiveness of the proposed solutions on a smaller scale before full-scale implementation.

Pilot Testing

Pilot testing involves implementing the proposed solutions in a limited area or process. This allows organizations to evaluate the effectiveness of the solutions and make necessary adjustments before rolling them out on a broader scale.

Monitoring and Control

After implementing the solutions, monitoring, and control mechanisms are established to ensure sustained improvements. Key performance indicators are tracked, and process controls are put in place to prevent deviations and maintain the desired level of performance.

5. Control Phase

Standardization

In the Control phase, standardized processes and procedures are developed to ensure consistency and prevent regression to the previous state. Standardization helps embed the improvements into the organization’s culture and ensures long-term sustainability.

Documentation

Thorough documentation of the improved processes and practices is crucial for knowledge sharing and future reference. This documentation serves as a guide for employees, enabling them to understand and follow standardized procedures.

Training and Development

Training and development initiatives are conducted to equip employees with the necessary skills and knowledge to implement and sustain the improvements. Continuous learning and skill enhancement are essential for maintaining improved process performance.

Continuous Improvement

The Six Sigma DMAIC process emphasizes the concept of continuous improvement. Organizations are encouraged to regularly review and refine their processes, seeking new opportunities for optimization and staying ahead of the competition.

Conclusion

The Six Sigma DMAIC process is a powerful methodology for enhancing business efficiency.

By systematically defining, measuring, analyzing, improving, and controlling processes, organizations can reduce defects, enhance customer satisfaction, and drive overall performance improvement.

Implementing the DMAIC process requires commitment, data-driven decision-making, and a culture of continuous improvement.

For individuals interested in gaining expertise in Lean & Six Sigma, we highly recommend enrolling in our comprehensive course, “Certificate in Lean & Six Sigma.” This program equips participants with the necessary knowledge and skills to effectively implement Lean and Six Sigma methodologies in their organizations.

FAQs (Frequently Asked Questions)

What are the key benefits of implementing the Six Sigma DMAIC process?

The Six Sigma DMAIC process offers several benefits, including improved quality, reduced defects, increased customer satisfaction, enhanced efficiency, and data-driven decision-making.

How long does it take to complete a Six Sigma DMAIC project?

The duration of a Six Sigma DMAIC project can vary based on its complexity and scope. Projects can range from a few weeks to several months, depending on the specific circumstances.

Can the Six Sigma DMAIC process be applied to any industry?

Yes, the Six Sigma DMAIC process is applicable across industries. It can be adapted and implemented in various sectors, including manufacturing, healthcare, finance, and service-based industries.

What are the common challenges in implementing the Six Sigma DMAIC process?

Common challenges in implementing the Six Sigma DMAIC process include resistance to change, lack of management support, limited data availability, and difficulty in sustaining improvements.

How does the Six Sigma DMAIC process differ from other problem-solving methodologies?

The Six Sigma DMAIC process distinguishes itself through its structured approach, focus on statistical analysis, and emphasis on data-driven decision-making. It provides a comprehensive framework for identifying, analyzing, and improving processes, making it a powerful tool for organizations seeking efficiency and quality improvement.

Aftab Khan is a logistics specialist with over forty years of experience in all aspects of supply chain and logistics management. He is an engineer by training and holds an MBA, besides several certifications from APICS/ASCM, ISCEA, and BRASI. Mr. Khan is the Executive Director of Business Research and Service Institute LLC, USA.