We stand on the brink of a technological revolution that will fundamentally alter the way we live, work, and relate to one another. In its scale, scope, and complexity, the transformation will be unlike anything humankind has experienced before. We do not yet know just how it will unfold, but one thing is clear: the response to it must be integrated and comprehensive, involving all stakeholders of the global polity, from the public and private sectors to academia and civil society.

The First Industrial Revolution used water and steam power to mechanize production. The Second used electric power to create mass production. The Third used electronics and information technology to automate production. Now the Fourth Industrial Revolution is building on the Third, the digital revolution that has been occurring since the middle of the last century. It is characterized by a fusion of technologies that is blurring the lines between the physical, digital, and biological spheres.

- 1784 – Steam, water, mechanical production equipment

- 1870 – Division of labor, electricity, mass production

- 1969 – Electronics, IT, automated production

- ? – Cyber-physical systems

There are three reasons why today’s transformations represent not merely a prolongation of the Third Industrial Revolution but rather the arrival of a Fourth and distinct one: velocity, scope, and systems impact. The speed of current breakthroughs has no historical precedent. When compared with previous industrial revolutions, the Fourth is evolving at an exponential rather than a linear pace. Moreover, it is disrupting almost every industry in every country. And the breadth and depth of these changes herald the transformation of entire systems of production, supply, management, and governance.

The possibilities of billions of people connected by mobile devices, with unprecedented processing power, storage capacity, and access to knowledge, are unlimited. And these possibilities will be multiplied by emerging technology breakthroughs in fields such as artificial intelligence, robotics, the Internet of Things, autonomous vehicles, 3-D printing, nanotechnology, biotechnology, materials science, energy storage, and quantum computing.

Already, artificial intelligence is all around us, from self-driving cars and drones to virtual assistants and software that translate or invest. Impressive progress has been made in AI in recent years, driven by exponential increases in computing power and by the availability of vast amounts of data, from software used to discover new drugs to algorithms used to predict our cultural interests. Digital fabrication technologies, meanwhile, are interacting with the biological world on a daily basis. Engineers, designers, and architects are combining computational design, additive manufacturing, materials engineering, and synthetic biology to pioneer a symbiosis

Challenges and opportunities

Like the revolutions that preceded it, the Fourth Industrial Revolution has the potential to raise global income levels and improve the quality of life for populations around the world. To date, those who have gained the most from it have been consumers able to afford and access the digital world; technology has made possible new products and services that increase the efficiency and pleasure of our personal lives. Ordering a cab, booking a flight, buying a product, making a payment, listening to music, watching a film, or playing a game—any of these can now be done remotely.

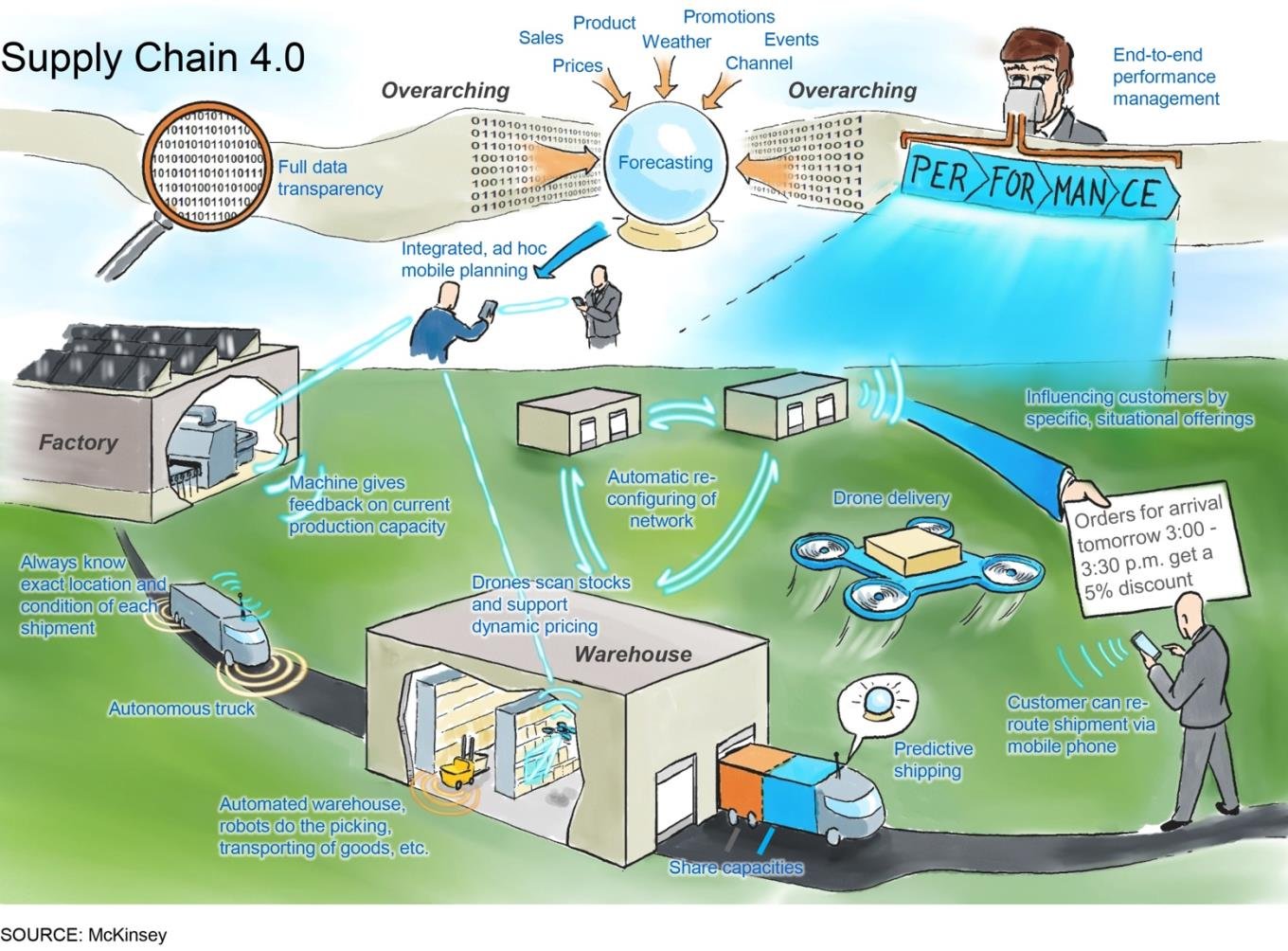

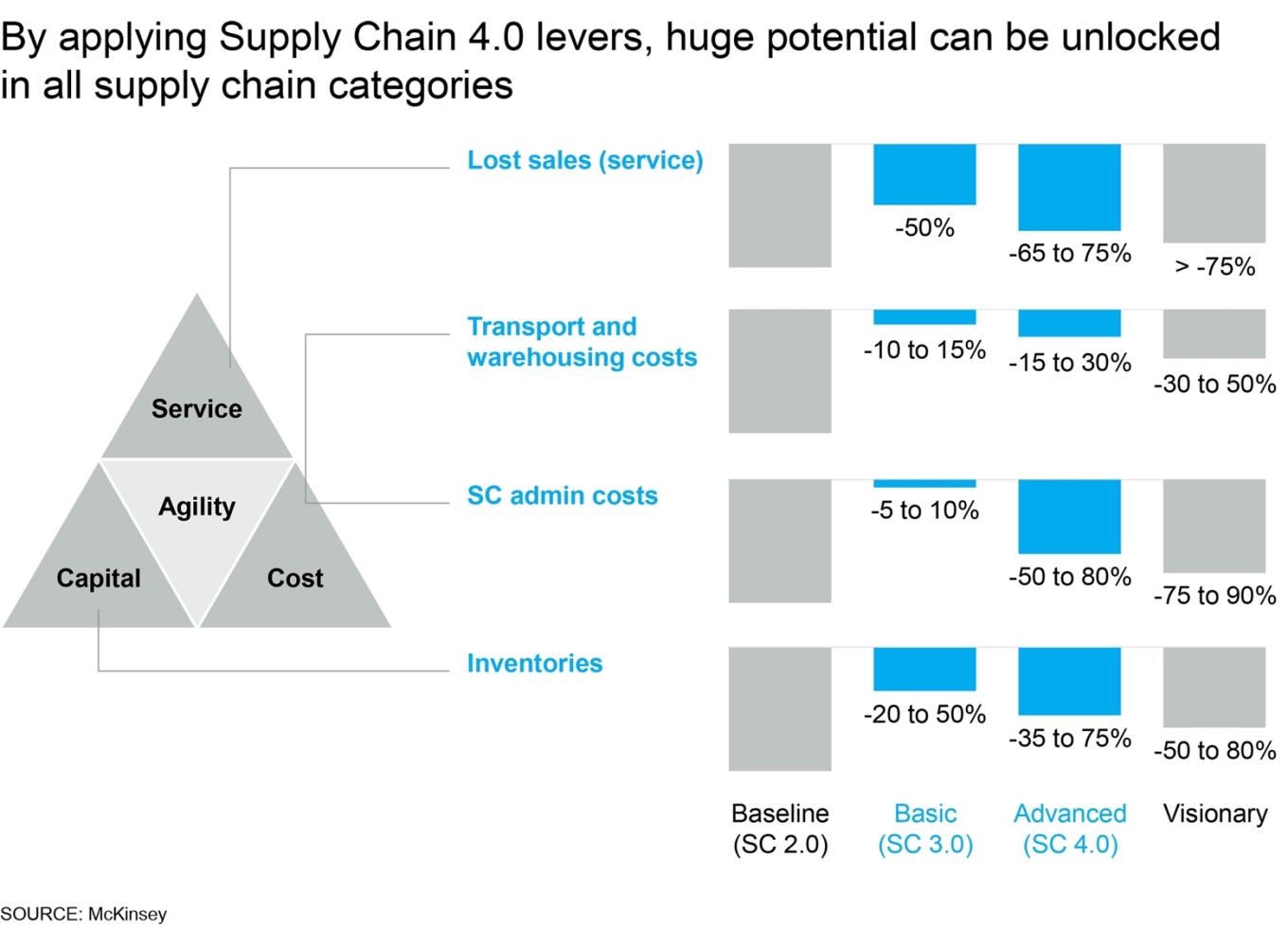

In the future, technological innovation will also lead to a supply-side miracle, with long-term gains in efficiency and productivity. Transportation and communication costs will drop, logistics and global supply chains will become more effective, and the cost of trade will diminish, all of which will open new markets and drive economic growth.

At the same time, as the economists Erik Brynjolfsson and Andrew McAfee have pointed out, the revolution could yield greater inequality, particularly in its potential to disrupt labor markets. As automation substitutes for labor across the entire economy, the net displacement of workers by machines might exacerbate the gap between returns to capital and returns to labor. On the other hand, it is also possible that the displacement of workers by technology will, in the aggregate, result in a net increase in safe and rewarding jobs as reverse chains and circular economies are both still in their infancy with the potential for dramatic job creation.

We cannot foresee at this point which scenario is likely to emerge, and history suggests that the outcome is likely to be some combination of the two. However, I am convinced of one thing—that in the future, talent, more than capital, will represent the critical factor of production and supply. This will give rise to a job market increasingly segregated into “low-skill/low-pay” and “high-skill/high-pay” segments, which in turn will lead to an increase in social tensions. Supply chains are as vulnerable to this segregation as any sector on the planet.

In addition to being a key economic concern, inequality represents the greatest societal concern associated with the Fourth Industrial Revolution. The largest beneficiaries of innovation tend to be the providers of intellectual and physical capital—the innovators, shareholders, and investors—which explains the rising gap in wealth between those dependent on capital versus labor. Technology is therefore one of the main reasons why incomes have stagnated, or even decreased, for a majority of the population in high-income countries: the demand for highly skilled workers has increased while the demand for workers with less education and lower skills has decreased. The result is a job market with a strong demand at the high and low ends, but a hollowing out of the middle. Supply chains themselves raise both economic and societal concerns as they fit well into this very mold.

This helps explain why so many workers are disillusioned and fearful that their own real incomes and those of their children will continue to stagnate. It also helps explain why middle classes around the world are increasingly experiencing a pervasive sense of dissatisfaction and unfairness. A winner-takes-all economy that offers only limited access to the middle class is a recipe for democratic malaise and dereliction.

Discontent can also be fueled by the pervasiveness of digital technologies and the dynamics of information sharing typified by social media. More than 30 percent of the global population now uses social media platforms to connect, learn, and share information. In an ideal world, these interactions would provide an opportunity for cross-cultural understanding and cohesion. However, they can also create and propagate unrealistic expectations as to what constitutes success for an individual or a group, as well as offer opportunities for extreme ideas and ideologies to spread.

The impact on supply chains

An underlying theme in my conversations with other supply chain executives is that the acceleration of innovation and the velocity of disruption are hard to comprehend or anticipate and that these drivers constitute a source of constant surprise, even for the best-connected and most well-informed. Indeed, across all industries, there is clear evidence that the technologies that underpin the Fourth Industrial Revolution are having a major impact on businesses.

On the supply side, many industries are seeing the introduction of new technologies that create entirely new ways of serving existing needs and significantly disrupt existing industry value chains. Disruption is also flowing from agile, innovative competitors who, thanks to access to global digital platforms for research, development, marketing, sales, and distribution, can oust well-established incumbents faster than ever by improving the quality, speed, or price at which value is delivered.

Major shifts on the demand side are also occurring, as growing transparency, consumer engagement, and new patterns of consumer behavior (increasingly built upon access to mobile networks and data) force companies to adapt the way they design, market, and deliver products and services.

A key trend is the development of technology-enabled platforms that combine both demand and supply to disrupt existing industry structures, such as those we see within the “sharing” or “on-demand” economy. These technology platforms, rendered easy to use by the smartphone, convene people, assets, and data—thus creating entirely new ways of consuming goods and services in the process. In addition, they lower the barriers for businesses and individuals to create wealth, altering the personal and professional environments of workers. These new platform businesses are rapidly multiplying into many new services, ranging from laundry to shopping, from chores to parking, and from massages to travel. New platforms for supply chain applications are on the horizon as well.

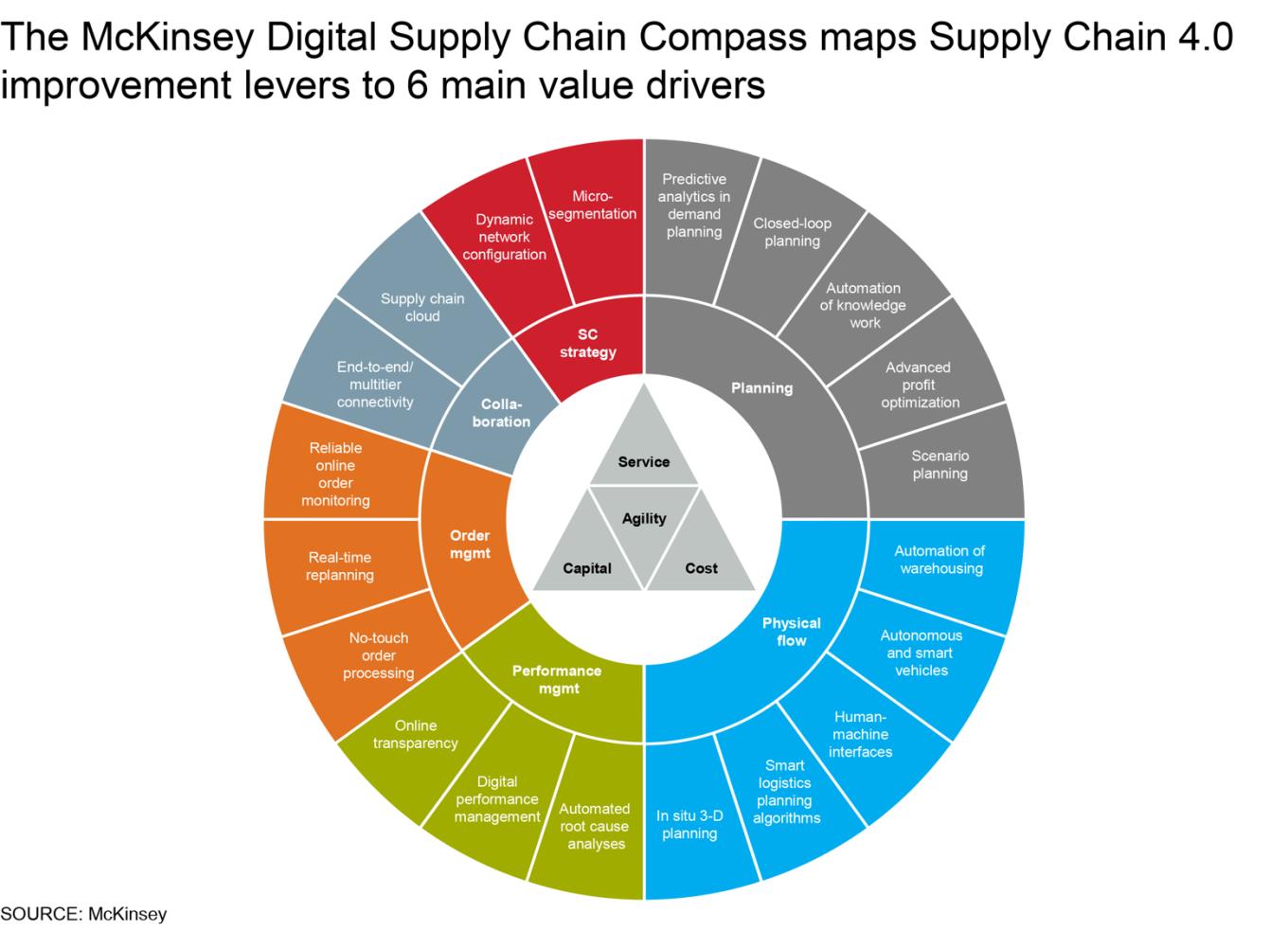

Overall, there are four main effects that the Fourth Industrial Revolution has on supply chains – on customer expectations, on product enhancement, on collaborative innovation, and on organizational forms. Whether consumers or businesses, customers are increasingly at the epicenter of the economy, which is all about improving how customers are served. Physical products and services, moreover, can now be enhanced with digital capabilities that increase their value. New technologies make assets more durable and resilient, while data and analytics are transforming how they are maintained. A world of customer experiences, data-based services, and asset performance through analytics, meanwhile, requires new forms of collaboration, particularly given the speed at which innovation and disruption are taking place. And the emergence of global platforms and other new business models, finally, means that talent, culture, and organizational forms will have to be rethought.

Overall, the inexorable shift from simple digitization (the Third Industrial Revolution) to innovation based on combinations of technologies (the Fourth Industrial Revolution) is forcing companies to reexamine the way they do business. The bottom line, however, is the same: business leaders and senior executives need to understand their changing environment, challenge the assumptions of their operating teams, and relentlessly and continuously innovate. Supply chains of the future may not yet have even been imagined.

The elimination of loading docks, wooden pallets, empty backhauls, and even distribution centers as we know them may soon be a reality as new technologies compete for their place. Consider the Cargo Carousel System being developed by Canadian supply chain consulting group MBSL. Bringing this innovation into the greater supply chain planning process offers tremendous strategic and performance potential. By leveraging the Cargo Carousel System as a callable capability and incorporating it into downstream transportation and upstream supply chain workflows, companies can improve asset utilization, use fewer trucks, drive fewer miles, have fewer empty backhauls/partial loads, reduce fuel costs, enhance distribution/retailing operations and increase recycling around the world by an order of magnitude. This is the sort of innovation that is changing the landscape.

The supply chain has not seen a game-changing innovation since the introduction of the ISO intermodal container back in the 50s. Supply chains are as old as civilization itself and currently lack the efficiency and sustainability required for today’s world and the fourth industrial revolution.

The impact on the government

As the physical, digital, and biological worlds continue to converge, new technologies and platforms will increasingly enable citizens to engage with governments, voice their opinions, coordinate their efforts, and even circumvent the supervision of public authorities. Simultaneously, governments will gain new technological powers to increase their control over populations, based on pervasive surveillance systems and the ability to control digital infrastructure. On the whole, however, governments will increasingly face pressure to change their current approach to public engagement and policymaking, as their central role of conducting policy diminishes owing to new sources of competition and the redistribution and decentralization of power that new technologies make possible.

Ultimately, the ability of government systems and public authorities to adapt will determine their survival. If they prove capable of embracing a world of disruptive change, subjecting their structures to the levels of transparency and efficiency that will enable them to maintain their competitive edge, they will endure. If they cannot evolve, they will face increasing trouble.

This will be particularly true in the realm of regulation. Current systems of public policy and decision-making evolved alongside the Second Industrial Revolution when decision-makers had time to study a specific issue and develop the necessary response or appropriate regulatory framework. The whole process was designed to be linear and mechanistic, following a strict “top-down” approach.

But such an approach is no longer feasible. Given the Fourth Industrial Revolution’s rapid pace of change and broad impacts, legislators and regulators are being challenged to an unprecedented degree and for the most part, are proving unable to cope.

How, then, can they preserve the interest of the consumers and the public at large while continuing to support innovation and technological development? By embracing “agile” governance, just as the private sector has increasingly adopted agile responses to software development and business operations more generally. This means regulators must continuously adapt to a new, fast-changing environment, reinventing themselves so they can truly understand what it is they are regulating. To do so, governments and regulatory agencies will need to collaborate closely with businesses and civil society.

The Fourth Industrial Revolution will also profoundly impact the nature of national and international security, affecting both the probability and the nature of the conflict. The history of warfare and international security is the history of technological innovation, and today is no exception. Modern conflicts involving states are increasingly “hybrid” in nature, combining traditional battlefield techniques with elements previously associated with nonstate actors. The distinction between war and peace, combatant and noncombatant, and even violence and nonviolence (think cyberwarfare) is becoming uncomfortably blurry.

As this process takes place and new technologies such as autonomous or biological weapons become easier to use, individuals and small groups will increasingly join states in being capable of causing mass harm. This new vulnerability will lead to new fears. But at the same time, advances in technology will create the potential to reduce the scale or impact of violence, through the development of new modes of protection, for example, or greater precision in targeting.

The impact on people

The Fourth Industrial Revolution, finally, will change not only what we do but also who we are. It will affect our identity and all the issues associated with it: our sense of privacy, our notions of ownership, our consumption patterns, the time we devote to work and leisure, and how we develop our careers, cultivate

our skills, meet people, and nurture relationships. It is already changing our health and leading to a “quantified” self, and sooner than we think it may lead to human augmentation. The list is endless because it is bound only by our imagination.

I am a great enthusiast and early adopter of technology, but sometimes I wonder whether the inexorable integration of technology in our lives could diminish some of our quintessential human capacities, such as compassion and cooperation. Our relationship with our smartphones is a case in point. Constant connection may deprive us of one of life’s most important assets: the time to pause, reflect, and engage in meaningful conversation.

One of the greatest individual challenges posed by new information technologies is privacy. We instinctively understand why it is so essential, yet the tracking and sharing of information about us and our consumption is a crucial part of the new connectivity. Debates about fundamental issues such as the impact on our inner lives of the loss of control over our data will only intensify in the years ahead. Similarly, the revolutions occurring in biotechnology and AI, which are redefining what it means to be human by pushing back the current thresholds of life span, health, cognition, and capabilities, will compel us to redefine our moral and ethical boundaries.

Shaping the future

Neither technology nor the disruption that comes with it is an exogenous force over which humans have no control. All of us are responsible for guiding its evolution, in the decisions we make on a daily basis as citizens, consumers, and investors. We should thus grasp the opportunity and power we have to shape the Fourth Industrial Revolution and direct it toward a future that reflects our common objectives and values.

To do this, however, we must develop a comprehensive and globally shared view of how technology is affecting our lives and reshaping our economic, social, cultural, and human environments. There has never been a time of greater promise, or one of greater potential peril. Today’s decision-makers, however, are too often trapped in traditional, linear thinking, or too absorbed by the multiple crises demanding their attention, to think strategically about the forces of disruption and innovation shaping our future.

In the end, it all comes down to people and values. We need to shape a future that works for all of us by putting people first and empowering them. In its most pessimistic, dehumanized form, the Fourth Industrial Revolution may indeed have the potential to “robotize” humanity and thus deprive us of our hearts and soul. But as a complement to the best parts of human nature—creativity, empathy, stewardship—it can also lift humanity into a new collective and moral consciousness based on a shared sense of destiny. It is incumbent upon us all to make sure the latter prevails.

What is the Fourth Industrial Revolution?

The Fourth Industrial Revolution, also known as Industry 4.0, involves the adoption of cyber-physical systems like the Internet of Things and the Internet of Systems.

Internet of Things:

Also known as IoT, the Internet of Things is a network of interconnected smart devices that allow each separate device to interact (i.e. send or receive data) with other devices on the network.

Internet of Systems:

Business-owned systems that can collect data from IoT networks to make independent decisions about your business’ marketing campaigns, sales, etc.

As the Internet of Things becomes more mainstream, smart devices will have more access to data which could allow them to become more independent. Eventually, smart devices might have enough information to make autonomous make decisions and control key business processes like supply chains without human input.

Whether autonomous machines are a good or bad thing, largely depends on who you ask. Some envision a dystopian, hellish world straight out of a Sci-Fi film where robots have taken all the jobs leaving humans unemployed and miserable. Without employment, our lives would become meaningless leading to drug addictions, violence, and widespread public unrest.

Others, most, believe that robots would eradicate the rather dull aspects of our work and allow humans to focus on more challenging, fulfilling tasks leading to an overall happier and more productive society. Regardless, once the Fourth Industrial Revolution reaches full maturity, it’ll impact nearly every industry in every country.

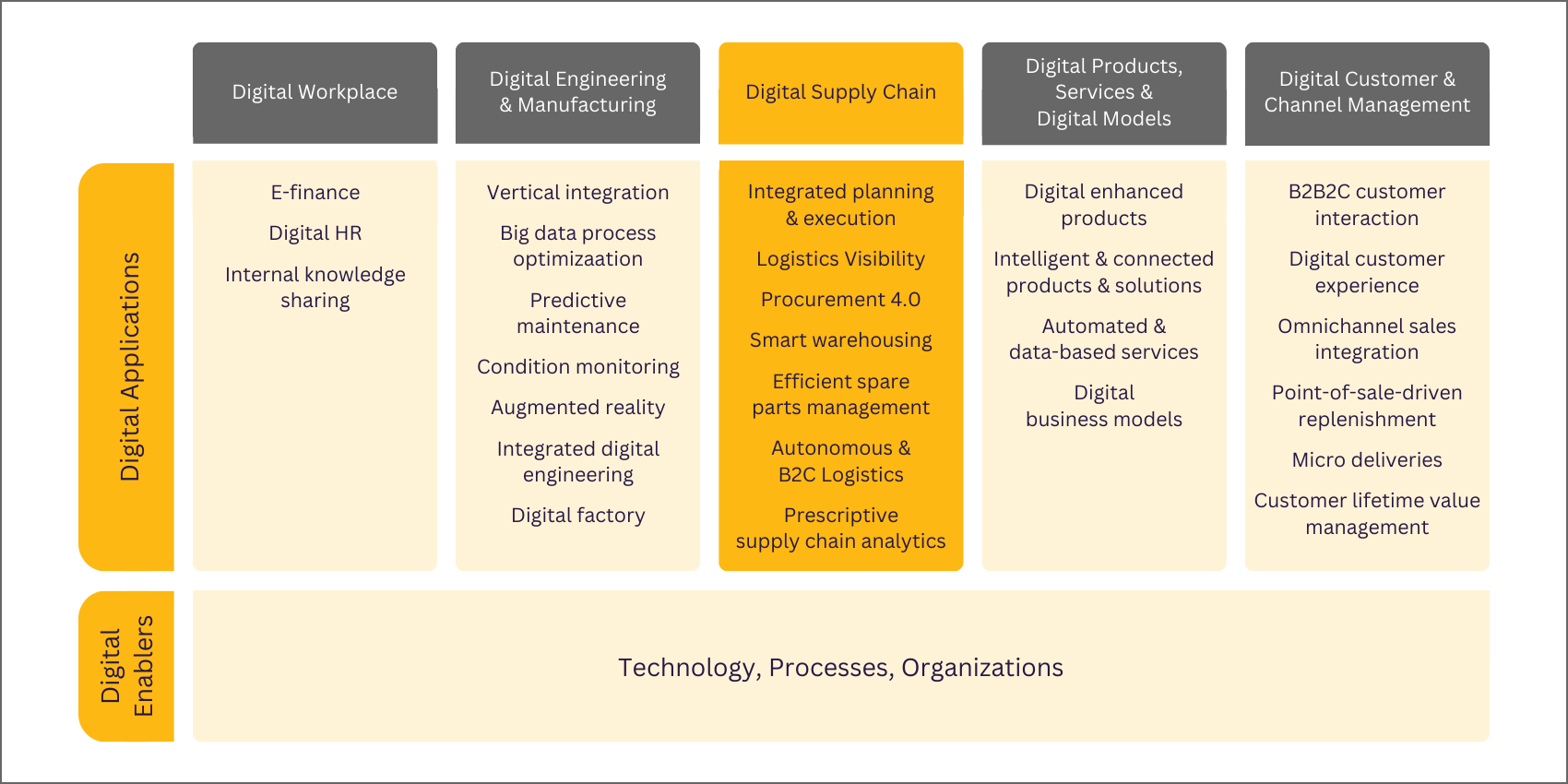

The Supply Chain at the Center of the Digital Enterprise

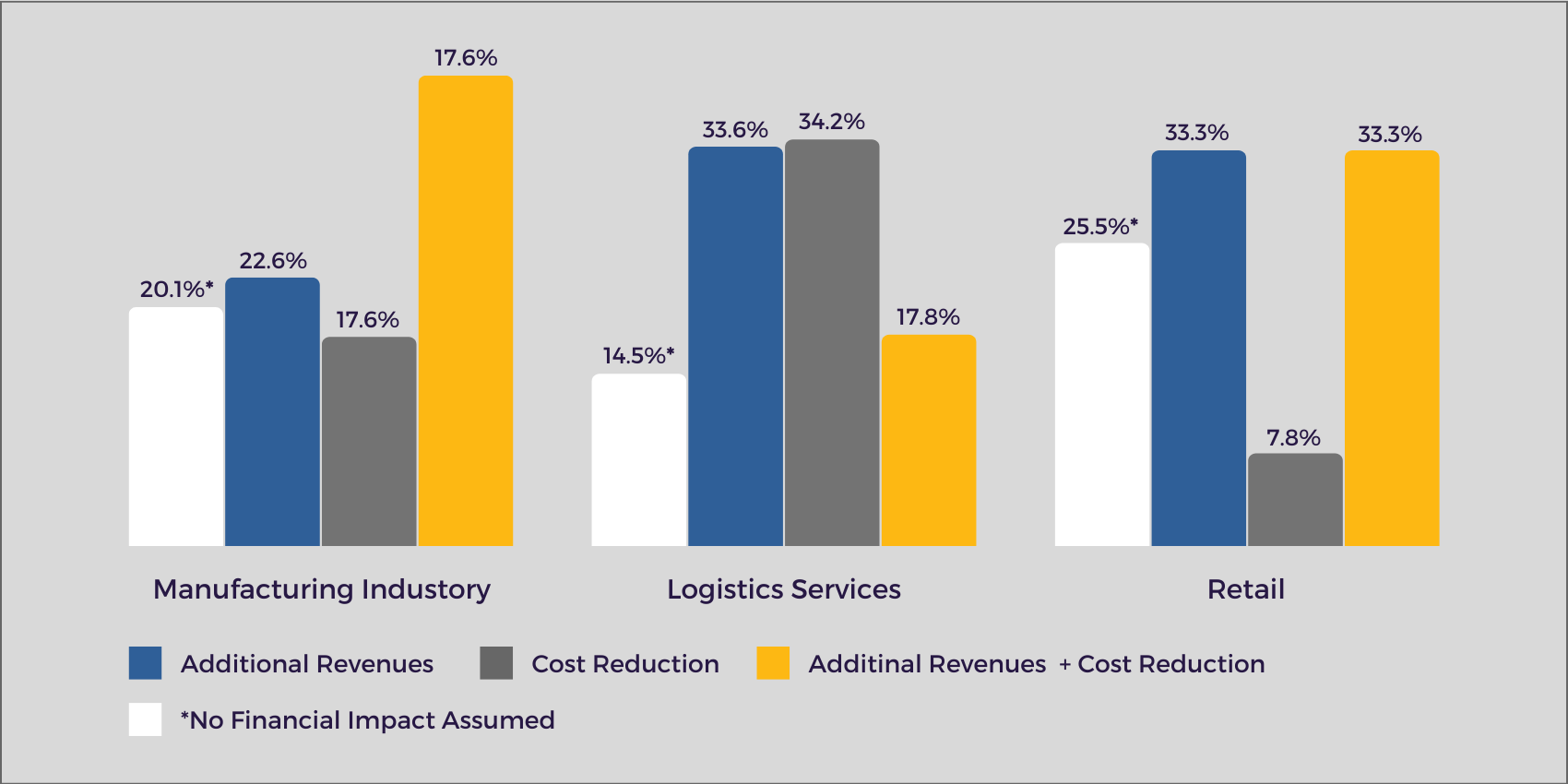

Expected Impact of Digital Transformation on the Cost Situation in Companies

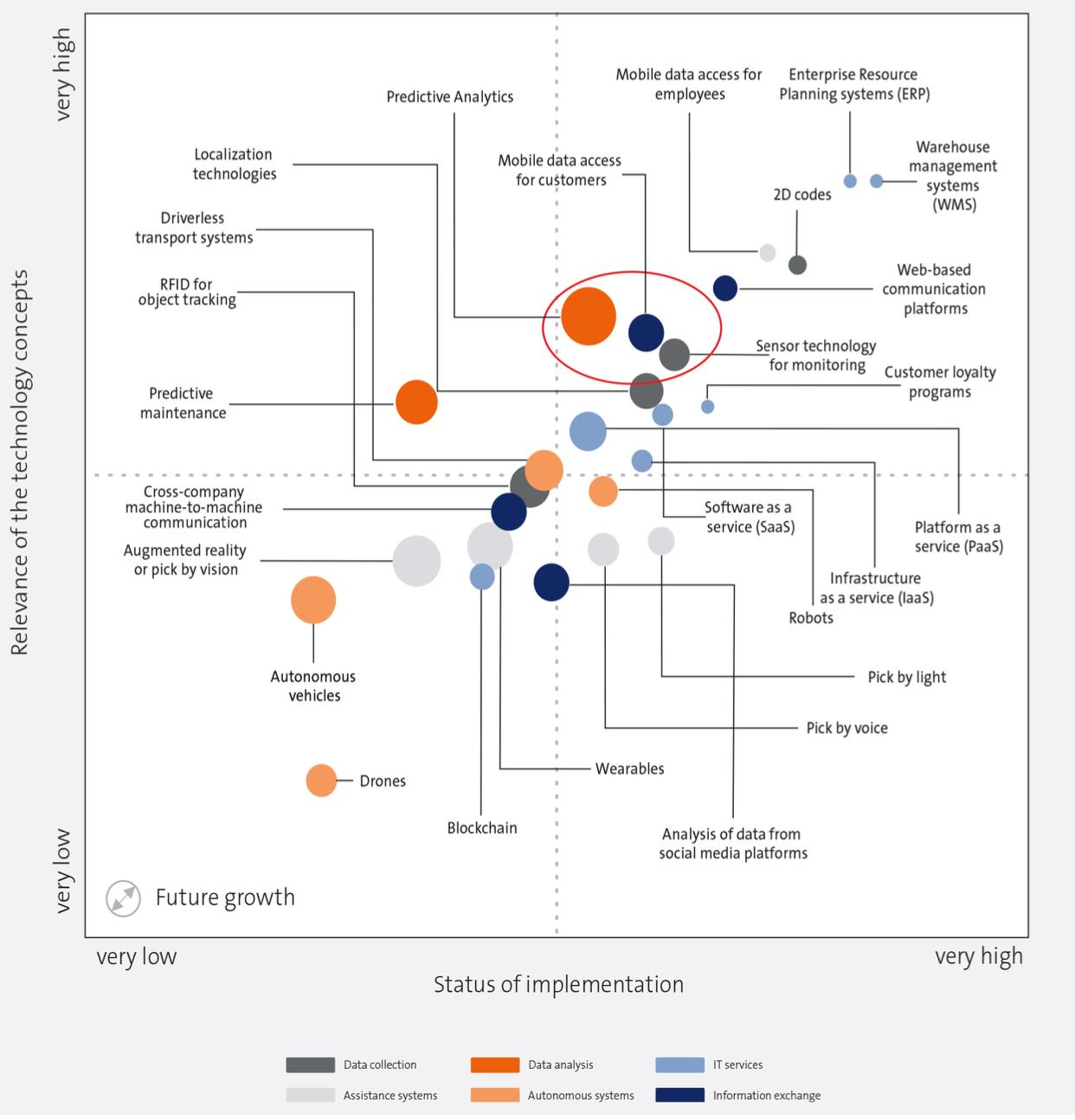

The Relevance and Implementation Status of the Technological Concepts Studied

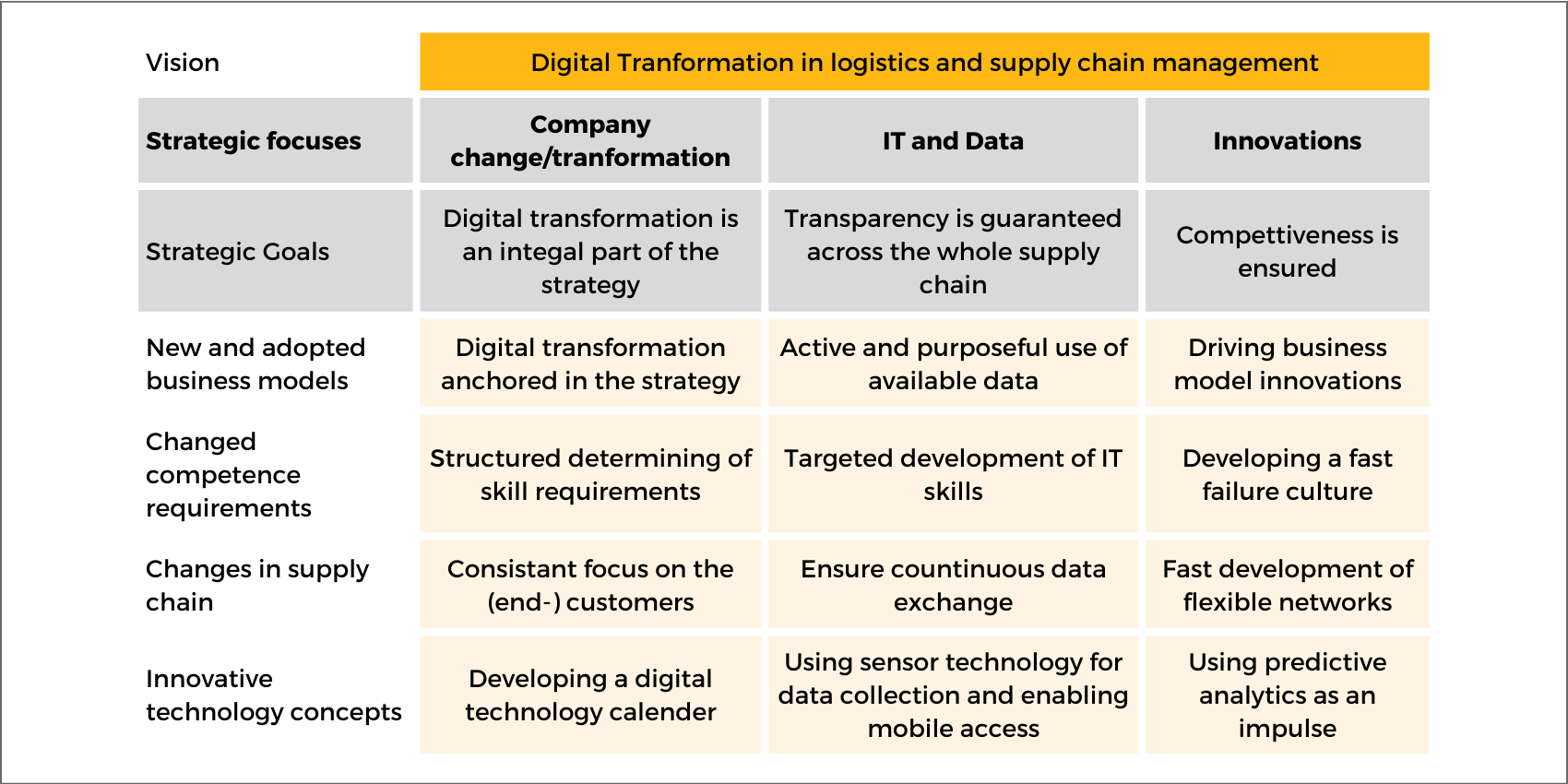

Strategy Map for Digital Transformation

What Impact Will the Fourth Industrial Revolution Have on the Future of Work?

The 4th Industrial Revolution is largely driven by four specific technological developments: high-speed mobile Internet, AI, automation, the use of big data analytics, and cloud technology. Of these four technologies, AI and automation are expected to have the most significant impact on employment figures within the global workforce.

A recent study released by McKinsey Global Institute reports that roughly one-fifth of the global workforce will be impacted by the adoption of AI and automation, with the most significant impact in developed nations like the UK, German, and US. By 2022, 50% of companies believe that automation will decrease their numbers of full-time staff and by 2030, robots will replace 800 million workers across the world.

While these figures may sound depressing, they may also simply represent a change within the workforce and displaced employees could, with the right skills, take on more beneficial roles. The World Economic Forum reports that 38% of businesses believe AI and automation technology will allow employees to carry out new productivity-enhancing jobs while over 25% of companies think automation will result in the emergence of new roles.

Remote working

In addition to new roles and responsibilities, the 4th Industrial Revolution could also lead to more companies employing specialist contractors or remote workers. Due to new technology and changing demands, employers may also become more supportive of existing employees wanting to work remotely or have flexibility.

Giving potential and current employees more freedom to work how, when, and where can be very beneficial for companies. It can allow them to recruit a global workforce, increase employee loyalty and commitment, scale at a quicker pace, and reach new levels of productivity. Employees benefit too as not having to commute means they’ll have more free time, a better work-life balance, and greater flexibility leading to overall employee satisfaction and commitment.

What jobs are the most likely to be impacted?

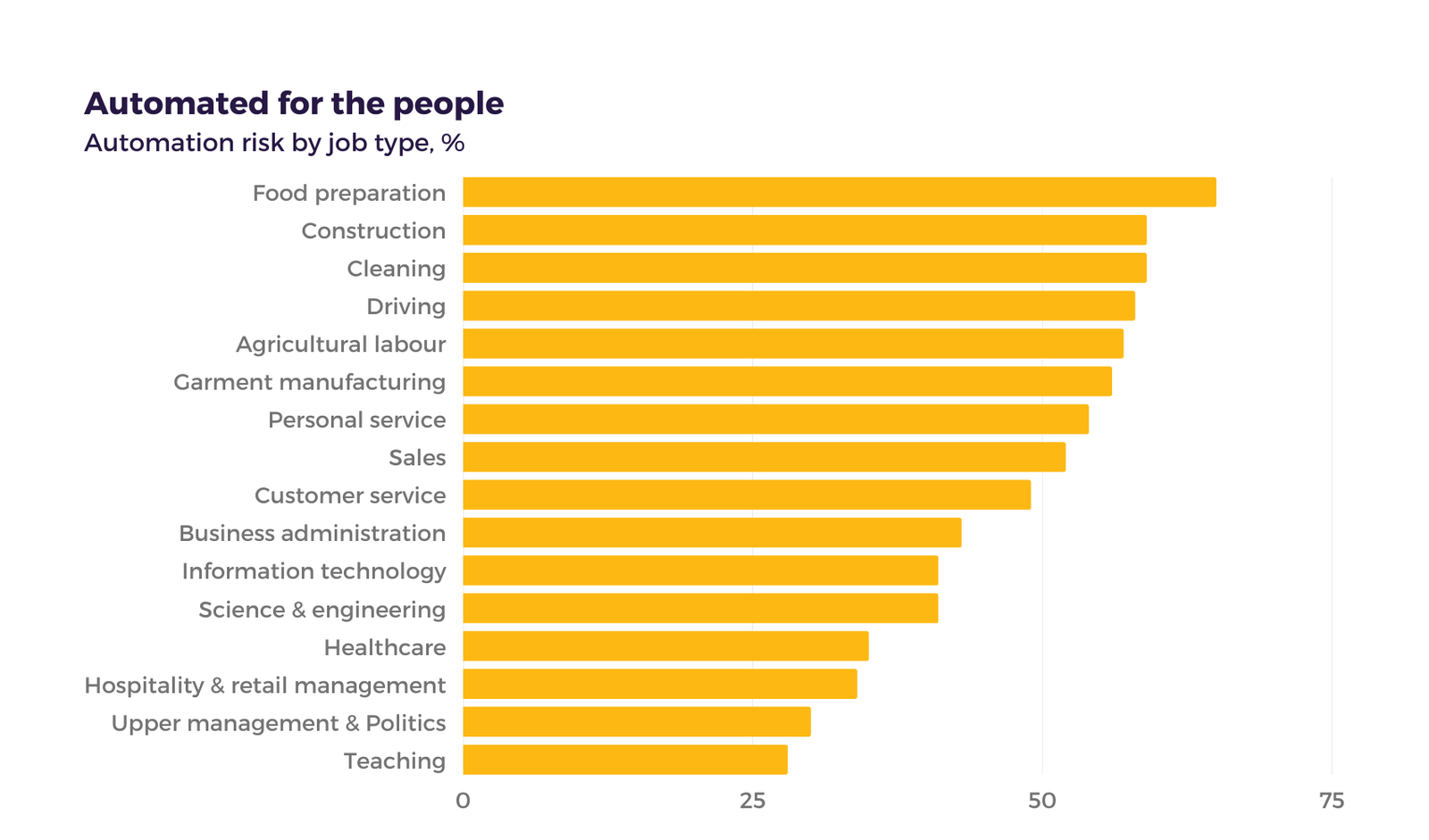

The 4th Industrial Revolution will impact nearly every industry with The Economist predicting that 50% of jobs are vulnerable to automation. However, some industries are more likely to be automated than others as robots, like human employees, have a particular specific skill set.

Within the near future, we can expect to see a reduction in the number of full-time staff in manufacturing and agricultural roles as many of these positions are already being phased out due to increased automation. Robots can also more effectively and safely handle tasks within industrial plants and as such their use in manufacturing dates back as early as the 1970s.

The OECD released a list showing the likelihood of roles, within specific industries, becoming obsolete or automated. At the top of the list are occupations within the food preparation, construction, cleaning, driving, and agricultural sectors.

In addition to manufacturing roles, automation may also impact postal and courier services, shipping and delivery, and service industry jobs. Don’t see your industry on the list? BBC has put together a handy calculator to help you determine how likely it is that a robot will replace you.

Jobs least likely to be impacted

While robots may be better at quickly, efficiently, and safely completing physical, predictable tasks, robots aren’t better at everything. Currently, most robots lack social and cognitive skills. They might be able to work as chatbots to answer customer questions and complaints within a given framework, but they generally lack enough empathy to adequately support or care for customers and patients.

As a result, roles that involve recognizing cultural sensitivities, caring for others, creative or complex reasoning or perception, and manipulation are unlikely to be automated. So, social workers, nurses, nuclear engineers, teachers, and writers can rest assured that they won’t be replaced by robots any time soon.

The 4th industrial revolution’s impact on the recruitment industry

According to the 2018 Global Trends report released by LinkedIn, 76% of recruiters and hiring managers think that the 4th Industrial Revolution, or more specifically automation and AI, will have a significant impact on the recruitment industry. Specialist recruiters, especially within sectors that are highly vulnerable to automation, may need to upskill or shift their focus to a new discipline to stay in the game.

Not only will recruiters have to deal with job losses across industries, but aspects of their roles could also be automated. Robots are already being used in the recruitment industry to make recruiters’ jobs easier, quicker, and more fulfilling. When it comes to talent acquisition, it can be easy to get bogged down in admin tasks like screening resumes or scheduling interviews. Over 52% of talent acquisition leaders admit that their biggest challenge is matching the right candidate to the right role.

AI technology can help. Intelligent screening software, like Ideal, can help recruiters process large volumes of CVs to find the ideal candidate. It examines current employees’ skill sets and attributes to find the perfect candidate to join the team. It can even pull information about the candidate from their social media profile or open-source company databases. Chatbots can be used to answer candidates’ questions or provide feedback and online interview software can be used to analyze interviewees’ answers including their word choice, speech patterns, and facial expressions to determine their suitability for the role.

Such innovative technology poses both an opportunity and a threat to recruiters. On the one hand, AI technology could allow recruiters to work faster and smarter by streamlining front-end processes, removing boring and dull tasks, and ultimately improving the clients’ and candidates’ experience. On the other hand, as AI technology becomes smarter, it could eventually replace recruiters.

BBC reports that human resource administrative workers have an 89.7% chance of being replaced by a robot. However, human resource managers or directors only have a 32.2% chance of being replaced by a robot.

Future of work

“These transformations, if managed wisely, could lead to a new age of good work, good jobs and improved quality of life for all, but if managed poorly, pose the risk of widening skills gaps, greater inequality and broader polarization.” – World Economic Forum, 2018 Report

On some level, workforce changes and technological advancements are normal and to be expected of any developing society. Some worry that the 4th Industrial Revolution could create a dystopian world where robots have taken our jobs and there’s a massive wealth disparity between those that own the robots and

those that don’t. However, automating key tasks could eradicate the more tedious aspects of our jobs and allow human employees to focus on more meaningful, fulfilling tasks.

Here at Change Recruitment, we prefer to think that the Fourth Industrial Revolution will have a mostly positive impact on the future of work. It’ll allow us to focus on more meaningful tasks and help people across every industry complete their jobs to a higher standard. We’re excited about the upcoming changes and are currently looking for ways to integrate AI technology into our workplace.

Evolution of Industry 4.0 and Its Implications for International Business

Introduction

Industry 4.0 has both expanded the possibilities of digital transformation and increased its importance to manufacturing, with an emphasis on globalization, international trade, and foreign direct investments. Industry 4.0 combines and connects digital and physical technologies including artificial intelligence, the Internet of Things, additive manufacturing, robotics, cloud computing, and others to drive more flexible, responsive, and interconnected enterprises capable of making more informed decisions [1]. The infusion of digital technologies in the value chain processes of research and development, design, production, marketing, distribution, and customer services will drive efficiency in production, thereby increasing the ambits of international trade.

Developed in Germany, currently, Industry 4.0 has become the most discussed issue in the industrial arena in the world. Both managers and policymakers from developed, emerging, and developing countries are debating this issue about how they can participate in this fourth industrial revolution as well as save them from the fallout of this advancement. The issue is still evolving, and experts from all spheres of industry and markets are debating on it. The objective of this chapter is to participate in this debate and explore how Industry 4.0 will evolve in the coming years and how it might affect international trade and the global value chain. We will take an in-depth look into what exactly is Industry 4.0 in our globalized context, what it brings to the table when it comes to international businesses, and how international organizations can benefit from Industry 4.0 in their globalization strategies? As a matter of fact, Industry 4.0 outperforms the previous industrial revolutions we have gone through during the past centuries. The fourth industrial revolution is the result of the combination between the real and the virtual world, in which deep learning encourages and challenges human capacities and frontiers, particularly, with the increase of cyber-physical systems. Indeed, the new industrial revolution which develops deep learning is not limited to the use of automation systems based on machine learning, but autonomous ones that do not systematically depend on human beings and which can learn and act by themselves. Industry 4.0 refers to many concepts such as artificial intelligence, smart technologies, smart factories, smart automation, or smart management like the implementation of enterprise resource planning and automation of robotized processes. The global business environment has already started to enhance efficiency with futuristic and high-value-added technologies, from which we are not able to see the frontier clearly for now.

Firstly, we will undertake a brief literature review to explain how we structured our work. We will then be having a great detailed analysis of Industry 4.0 and its main components and how it is changing the way corporations do business in an increasingly connected world. Parallelly, we will explore the opportunities that the fourth industrial revolution brings as well as the challenges which emerged from this new revolution in order to counterbalance and give a realistic view of the latter. Finally, we will

illustrate the major strategies that can enable the organization to avail opportunities emanating from Industry 4.0.

Opportunities and strengths of industry 4.0

Industry 4.0 contributes to the virtualization of a physical production environment that facilitates connectivity and interaction between the machines as well as man and machines in real time. Automation and connectivity as well as machine learning facilitate inter-connectivity and improve the production process and bring several benefits to the organization. Some of them are presented in the following sections.

Generator of efficiency

Industry 4.0 is a generator of efficiency. Indeed, the great use of technologies within the different steps in the supply chain helps with optimizing the latter. It is, therefore, cost-effective, and time-effective and it globally enhances productivity as well as flexibility and quality of outputs, which also raises the overall reliability of the firm and so the value of the company and its competitiveness. Industry 4.0 is not only about using high-technology machines to produce more rapidly. There is indeed much more to that. Industry 4.0 can contribute to streamlining the value chain thanks to its transformation of every aspect of the production process from the logistics, passing through the managerial issues, to the networks, and more generally, the whole structure of firms in the network.

First, firms can benefit from advanced planning and controlling with relevant, real-time data. Indeed, the collection and great use of data help with a greater inner and outer communication and organization, even from an international perspective: from a headquarter in Quebec City (Canada) to a manufacturer in Dhaka City (Bangladesh), for instance. Planning is simple and effective, accessible for all employees who need to access it, and can be easily changed. The improvement of communication also implies greater control of the organization thanks to easy access to information, anywhere, anytime.

Data is the basis of all the improvements around artificial intelligence and the comprehension of the opportunities that can be taken in organizations. Used correctly, data and communication tools can help firms to better respond to customers’ demands and allow a better accuracy of forecasts too. Data within the industry can help to see what should be improved in terms of production methods to gain efficiency. In that sense, they can also more easily identify bottleneck products which would result in better opportunity costs. Firms can also benefit from greater management and control thanks to adapted software within the firm. Data can be used to analyze production time and costs, as well as comparisons of portfolios of suppliers and materials to get the best of their interest. It allows a rapid reaction to changes and errors. It also allows a quick adaptation when it comes to stock levels, wherever it is from the production or the purchasing teams’ perspectives. Finally, data is the base of artificial intelligence. Thanks to machine learning, data is used to learn from mistakes and successes, which is crucial to exponentially improving.

Thanks to data, programs are elaborated to improve the business networks such as suppliers with industries or with clients, or from clients to employees when they make a requirement for a change in the process of making an order. Communication is smoother, quicker, and easier to take action. Technologies also allow better safety of work conditions. The efficiency of new technologies allows companies to be more sustainable thanks to smart production facilities, which allow a better allocation of resources and vertical networking of smart production systems. The vertical networking of smart production systems can be defined as Smart factories and smart products, and the networking of smart logistics, production and marketing, and smart services, with a strong needs-oriented, individualized, and customer-specific production operation [3]. Most firms affirm that Industry 4.0 and its innovations contribute to efficiency and profitability. Industry 4.0 gives companies a better competitive advantage. This has a great impact on a company’s profitability. This is partially due to a reduction in costs from the efficient use of resources. On top of this, we can observe the benefits of Industry 4.0 through its four main components.

The vertical networking of smart production systems:

Vertically integrated Smart productions use deeply integrated data in order to rapidly orient the production in a customer-specific direction depending on the demand and the stock levels. The production is monitored by cyber-production systems (CPS) and smart sensor technologies (SST) that automatize the organization, making it autonomous. As a result, the maintenance and management of production systems are optimized. All the processes at all stages and the resources that come with them are logged, which helps to perpetually update the fluctuations and adapt quickly to any movement of these factors. In a nutshell, the goal of this vertically integrated system is the efficiency of resources, and the satisfaction of specific, individual requirements of customers. These advanced systems allow firms to communicate in real-time with their supply chain partners across the globe, from producers to clients and suppliers, and consequently to adjust their global supply chain on a continuous basis.

Horizontal integration via a new generation of global value chain networks:

Horizontal integration is a new model of the value-creation network: optimized real-time networks that enable integrated transparency, offer a high level of flexibility to respond more rapidly to problems and faults and facilitate better global optimization. Similarly, to the previous model of integration, horizontal integration works via CPS, in order to log and meet all the logistics challenges continuously (traceability, accessibility, management of warehouses, and production). Processes are therefore more flexible in every step of the value chain. Modifications and adaptations following the customer’s requirement can be made at any level.

Through-engineering across the entire value chain:

The third main characteristic of Industry 4.0 is cross-disciplinary through-engineering across the entire value chain and across the full life cycle of both products and customers. It consists of the development of integrated and coordinated product-life-cycle production systems that creates an optimization of the relation between the production systems and the product development. The key to this component of I4.0 is also the deep integration of data, used at every step of the value chain.

Acceleration through exponential technologies:

The fourth main benefit of I4.0 is its impact on flexibility, individualization, and cost savings in terms of industrial processes thanks to its ever-growing set of innovative solutions.

Autonomy:

Artificial Intelligence allows automation systems to be highly cognitive and autonomous thanks to advanced robotics and sensor technology that can perfect each individual production process.

Safety and quality:

Nanomaterials and nano-sensors allow the close monitoring of production for better quality assessment and safer collaboration of humans with next-generation robots.

Automated logistics:

The use of AI-programmed machines like drones to make inventories, and driverless vehicles in factories and warehouses to deliver components is particularly efficient thanks to their ability to function day and night under any weather conditions. These logistics solutions of smart factories allow for cost-cutting, flexibility, reliability, and time savings.

3D printing:

Additive manufacturing (3D Printing) brings new functionalities and higher complexity of products without additional costs and new inventory management solutions thanks to delayed differentiation of products allowing for smaller stocks, and supply chain risk pooling between different factories. There are, however, still challenges to overcome before additive manufacturing can make an impact on manufacturing sectors given the fact that this technology is still expensive and unit cost of production is high and does not follow economy of scale principles.

Customization

The most blatant of the effects of efficiency in this modern revolution is customer satisfaction. Indeed, thanks to the advanced technologies, customers’ demand is well – if not above expectations – aligned with the market’s needs and wants while remaining highly profitable for the firm.

Customization is an important issue in the global manufacturing industry, and its relevance is expected to even increase in the future. Customers want to customize the design of their products by influencing the development and production processes at an early or even late stage. This tendency creates the need for manufacturing companies to move from the objective of better products for their customers to the objective of an individualized understanding of customer needs and specialized, industry-specific solutions. A major shift from an economy of scale to an economy of customization regardless of the location of production sites in the global value chain.

This ongoing change in customers’ needs results in more and more system complexity in system design as well as in assembly. Furthermore, commissioning can only be partially compensated by manufacturers’ standardization and modularization efforts. Nevertheless, end-to-end product data modeling from engineering to commissioning enables efficient production at locations with a global presence and supply chain, as well as an efficient way to cope with the increasing product complexity resulting from the demand for customized system solutions. One way to implement individualization in the production process is through assembly line production systems. Modern assembly line systems have the increasing ability to offer each customer a different product that is better suited to their needs and preferences. These assembly line systems are enormously profiting from the upcoming Industry 4.0 technologies. Moreover, this development enables the proposal of business models covering product customization, i.e., customers can change the attributes of their product once production of the product has started. This business model requires manufacturing tools to be able to make decisions online and negotiate with the customer on the changes that can be made, depending on the workload flowing through the production system. The ability to make changes online also reduces the disadvantages of the large geographical distance between the manufacturer and the customer caused by international business activities.

Assembly line production systems will also be affected by an increase in flexibility in production. Products produced in assembly lines will not only be able to be personalized but that late customization (i.e., after the order has been placed) will also be possible because real-time information on the status of the production process will be available. This means that customers will not only be involved in the definition and design of the product and its specifications, as is the case with mass customization products but will also be launched once in a late customization mode.

In contrast, mass-customized production facilities typically produce large volumes of products that share a common core but may be customized to a certain degree, creating production process sections with repetitive larger lots (e.g., automotive press shop) and sections of high product variance (e.g., final automotive assembly). The customers of mass-customized production factories typically customize their products based on a predefined set of configuration options, which can be integrated into a common modular architecture. Mass-customized production-type factories are typical in the automotive industry, automotive Tier-1 suppliers, and, to some extent, in the truck, bus, agricultural, and construction equipment sectors. Industrial equipment manufacturers – where factories simultaneously have large production volumes and accommodate an ever-increasing number of variants – run mass- customized production type factories as well.

Therefore, the strategy of providing differentiated products leads to a paradigm change in manufacturing planning, posing new challenges for industrial activities. To satisfy the new kind of markets, industries had to adopt agile models, exploiting the competitive advantages of each organization. These manufacturing models intend to face the uncertainty of the market by increasing the response capability of the organization in order to satisfy the customers with similar costs to mass-production industries. Handling the production of large amounts of customized products presents a tough challenge since product differentiation hampers scale economies.

However, managing the production of personalized or customized goods will be quite demanding, given their different requirements. Finally, when late customization of the customer is possible to be accepted and when it is not, it depends on the production sequence in execution, and when it is possible to apply to re-sequence to incorporate the late customizations. Moreover, the advantages of late customization processes can be achieved only if the system is autonomous and can keep running the fabrication process. The customer needs real-time information about the evolution of the production of its personalized product.

Big data analytics

Before Industry 4.0, companies used traditional data sources such as production records, internal accounts, and market research reports with a limited range for their decision-making process. The way of data sourcing is changing. Data is more and more generated from sources like sensor-generated data from smart products and data from search engines and social media sites. This technological shift offers multinational companies (MNCs) the opportunity to access new worldwide business-relevant information. Additionally, technical progression regarding computing power and data storage costs is taking place. This results in the development of big data analytics.

To understand the innovational power of big data analytics, it is important to understand the changed concept of time in comparison to data analytics before Industry 4.0. Big data analytics is looking into the future and trying to generate existing and new data sources. The traditional role of information technology has been more backward-looking and concerned with monitoring processes and notifying management of anomalies. Firms that have adopted big data analytics report improvements in productivity and financial performance. For example, analysis of big data can enable managers to identify defects, faults, and shortcomings in the production process at an early stage, optimize automation processes and carry out trend analyses, use resources more efficiently, and carry out predictive maintenance.

The potential implications of big data analytics for international business are several. In particular, firms will be able to monitor emerging trends and opportunities in overseas markets without the need to make substantial resource commitments in those local marketing affiliates, and they will be able to optimize their supply, production, and distribution activities around the world. But there are two major drawbacks. The first is that the availability of good-quality big data may well be a source of value for firms, but successful firms will require a range of technical and governance capabilities to analyze and operationalize that data so as to realize the potential benefits. The second is that individuals’ privacy will be under threat from widespread big data applications. Like Facebook knows what we like, Google knows what we browse, and Twitter knows what is on our minds.

New data protection laws and/or stronger industry self-regulation will need to be formulated to safeguard the privacy of individuals and companies, and to put limits on what data can be accessed, stored, and transmitted both nationally and across borders. It has to be discussed who will have legal title over what, who will bear legal responsibility for, products that involve consumer-generated intellectual property and how will these issues be handled in cross-border settings? Some form of (transnational) governance regime will be necessary to regulate this dilemma between the benefits of big data analytics described earlier and data privacy. Finally, this may influence or even determine the abilities of firms to maximize the commercial potential of big data analytics.

Environmental impact: Energy sustainability

The optimization of production and logistics processes allowed by Industry 4.0 could have a major impact on the management of the environmental crisis. Indeed, the processes of Industry 4.0 that allow energy savings and waste reductions to cut costs for firms would be equally beneficial for the preservation of natural resources and biodiversity. The Sustainable Development Goals established by the United Nations include the improvement of energy efficiency and better management of waste. Therefore, the improvements brought by Industry 4.0 would be in adequation with government environmental policies and regulations, which will most probably become much stricter in the coming decades.

Industry 4.0 allows improved production management thanks to the production monitoring capabilities of Industry 4.0. Constant monitoring of production efficiency and intelligent quality control offer great opportunities in terms of production efficiency, waste reduction, and improved reliability. Consequently, firms would have better energy efficiency. Industry 4.0 allows firms to make informed decisions based on the data-mining possibilities brought by sensors and AI. Relevant statistics on production efficiency, product life cycle, and energy consumption will be available to the firms. Industry 4.0 will also connect the consumer with its energy consumption thanks to the sharing of statistics made possible by smart data communication technologies. Energy consumers will be informed about their consumption, and this will promote self-responsibilities.

However, these improvements could easily be counterbalanced by the fact that Industry 4.0 requires the collection and storing of massive quantities of data in data centers, which significantly contributes to global warming. But this is not a fatality, and firms should not be stopped by this challenge, as innovative solutions allow the heat produced by data centers to be reused as a heating source. This strategy is especially used in Nordic countries such as Finland or Sweden.

Evolution of Industry 4.0 and Implications for Global Business

Research on Industry 4.0 is numerous and rapidly evolving. Many types of research have addressed the evolution of the Industry 4.0 (I4.0) phenomenon and its contribution to international business activities. Especially the major drivers of I4.0 that underline its involvement to enhance current business practices by streamlining both the production and supply chain networks [30, 31]. Those developments in Industry 4.0 have huge implications on the way the current business activities both at home as well as across the globe (i.e., international trade) are being conducted. Mamad [2] has addressed how Industry 4.0 works and has made a broad illustration of the subject in detail through an exhaustive literature review. Deloitte [3] provided an overview of the beneficial application of Industry 4.0 to enhance organizational processes. McKinsey’s [6] study focused on customization and explained how Industry 4.0 has reshaped the manufacturing industry to fit customer demand and how companies can reap profit from these upcoming innovations by showing application opportunities. UNIDO [32] report has presented an impact analysis and showed how Industry 4.0 could contribute to environmental sustainability. Jayashree et al. showed how Industry 4.0 could contribute to developing dynamic capabilities and realizing triple bottom line (TBL) sustainability. Bibby et al. [34] give some tools to assess the current level of Industry 4.0 maturity of businesses that want to transition to I4.0 and better approach the issue. Dhanpat [35] reminds us of the underlying dimensions of I4.0 as a growing need for learning capacities of smart technologies to cope with the new era of cyber-physical systems. Ahmadi et al. [36] addressed the main architecture models of value-chain structure in Industry 4.0.

Industry 4.0 and international trade

Industry 4.0 brings both enormous opportunities and challenges for the industry and international trade. It helps not only to modernize the production process and self-initiated execution but also allows the managers to undertake the management of the production process across the globe by creating a flexible global supply chain.

Fourth industrialization is changing the way we perform different kinds of business activities by drawing its main components and their contribution to the business environment. Industry 4.0 is the implementation of cyber-physical systems for creating smart factories by using the IoT, big data, cloud computing, artificial intelligence (AI), and communication technologies for information communication in real-time between man-machine and machine-to-machine communication which is redefining the global value chain.

There are five key drivers of Industry 4.0: Digitalization, optimization, and customization of the production, automation, and adaptation, human and machine interactions, and collaborations, high value-added offers, and automatic exchanges of data and communication. The fourth industrialization has contributed to the critical transformation of the international business environment in the different stages of an organization such as human resources, financial systems, management, organizational structure, or production processes.

Those key drivers are highly illustrated by the implementation of cyber-physical systems, the internet of things, smart factories, smart technologies, cloud computing, and big data. The latest architecture of industrialization pursues new objectives and faces completely different challenges that increase from a global perspective. Industry 4.0 offers an opportunity of restructuring the declining manufacturing industry in a high-cost country (HCC) and permits it to maintain a strong industrial base in developed countries [38]. It could represent a great opportunity in the context of declining manufacturing in the developed markets.

Industry 4.0 answers three key challenges: better competitiveness, flexibility, and agility by facing global offer end demand fluctuation and the regionalization of production [38]. To sum up, Industry 4.0 can be understood as multiple solutions built to change the international industrial sector to gain stronger competitive positions, and market shares, especially within a risky business environment. This ambition should be realized by using smart technologies and factories that ensure efficient responses to the variation of the global market by improving competitiveness and agile management, which will conduct the changes implied by Industry 4.0.

Industry 4.0 and implications for international businesses

Central to the fourth industrial revolution is an interconnected network. The internet enables many small firms to participate in global trade, thus, leading to more inclusion. It makes it possible for more products to be exported to more markets, often by newer and younger firms. A 10-percent increase in internet use in the exporting country is found to increase the number of products traded between two countries by 0.4 percent. A similar increase in internet use of a country pair increases the average bilateral trade value per product by 0.6 percent [39]. The transformation implied by the fourth industrialization, Industry 4.0, might lead to significant changes in existing business models allowing new ways to create value. These changes are expected to result in the transformation of traditional value chains. Industry 4.0 affects three elements of manufacturing small and medium enterprises (SMEs): value creation, value capture, and value offer.

The 4th industrialization will completely change global value chains by transforming its practices and objectives. The purpose is not limited to monetary rewards but includes new trends such as the willingness to gain efficiency, create and sustain global competitive advantages, find new ways of producing, generate innovations, stimulate automation and learning, or even increase customer implications in the production processes.

Several opportunities generated by Industry 4.0 are transforming the current business levels and activities through its drivers. Multiple business models are flourishing in the Industry 4.0 era. One of their fast-emerging models of them is the expectation [40]. The expectation represents a combined model in which a firm built its expertise through the production processes of its general offer. This new trend led a company to create consulting services (about products or processes) or a new platform-based model. The platformization of the product refers to a company that uses its know-how and intensive capacities of production to create digital products that answer customer queries by using a cloud-based platform. The platformization of processes reflects the use of smart factories’ concepts and internal processes to transform their capacities into a digital platform. The value created is the result of an integrated solution of digital products and related information technologies services. The expectation gives us an illustration of how I4.0 changes our model to do business and how complex it is to put it in place within an organization and will impact the current business activities. The major Industry 4.0 drivers will redefine business activities [30].

The Internet of things (IoT) is retained as a pillar of I4.0. This type of technology provides access to the internet by using deep learning technologies. This equipment transforms machines into smart objects that could, for instance, detect wear, control the performance of the production process, plan the capacity, or even manage stocks in real time. Cloud computing allows interconnection between computers and the internet. It can solve many issues such as Big Data storage as well as the costs and capacities linked to this storage.

Cyber-physical systems (CPS) are mechanisms that allow Humans, software, and machines to interact. It implies an aggregate level of networking. The main purposes of this technique are, by creating such virtual interconnection, to exchange key information to make better strategic decisions. It establishes strong links between production processes, machines, and the virtual world, which work and communicate thanks to computation and the internet in real-time cooperatively. The machines and physical systems will be synchronized to software, and it will allow the control and assessment in real-time production efficiency, adjusting it and making the right strategic decisions easily. Also, CPS enhances the integration of autonomous machines and the collaboration between humans and cyber work.

Autonomous robots are created with deep learning capacities. Deep learning technological advances permit a robot endowed with artificial intelligence to adapt itself to its working environment, make adjustments that enhance its working environment, and take appropriate decisions when observing disruptive issues. This is one of the major pillars of I4.0 that is very challenging as it can replace Human works forward and generate greater benefit for a company. Enterprise resource planning (ERP) systems are considered the backbone of Industry 4.0 [41]. ERP systems, for instance, the system’s Applications and products in data processing (SAP) software, help companies in various areas, to manage better their processes, and enhance their efficiency by integrating their operations to increase flows of information and collaboration between the company and its partners. ERP systems help companies in many areas starting from increasing better information sharing between departments, improving workflow, better supply chain management, integrating data, processes, and technology in real-time across internal and external value chains, standardization of various business practices, improving orders management and accurate accounting information of inventory management [42].

The result of the use of the different drivers (IoT, CPS, Internet of Service, ERP) will lead to the creation of smart factories, which brings all the smart tools and models together in its production model. This integrated system will facilitate the globalization of production and expansion of the global supply chain. It is true that some manufacturing activities might be re-shored but at the same time, the new smart technology will allow firms to reconfigure their production network overlooking the national boundaries and distance. That is the reason why it is still in the pre-paradigmatic stage of Industry 4.0. implications it is a continuous process that conducts the transformation of our current or traditional methodologies to do business and conceive industrial purposes and processes. As a result, the production model of smart factories becomes cost-effective and flexible to market changes, and sustainable, which would reflect the highest level of effectiveness feasible to achieve. This newfound technological prowess will modify drivers of global production networks (GPN), reduce the importance of physical distance as well as re-configure the global value chain (GVC). The new global division of labor (NGDL) is likely to emerge and re-distribute the manufacturing activities integrating different hubs from both the developed, emerging, and developing markets.

Challenging Issues Related to Industry 4.0

There are no doubts about the enormous challenges that Industry 4.0 will bring to the current practice of production, consumption, and global value chain (GVC). Firms and policymakers need to take into consideration adequate strategies to better implement the Industry 4.0 systems, re-organize business activities by taking into consideration of new context and take other caution for the long-term growth of the fourth industrial revolution and reap profit from it. We will define and analyze in this section the challenges raised by Industry 4.0, starting with implementation challenges, then the challenges surrounding the management of Human resources, then the risks to data security, then the Big Data challenges, and finally, the challenges concerning the environment.

Implementation challenges and inequalities

As we established earlier, the transition to Industry 4.0 brings countless opportunities for businesses to increase their efficiency and development. However, there are many barriers to the implementation of Industry 4.0, the most important lackings are the shortage of skill sets that are required in the Industry 4.0 phenomenon. There is also a lack of experience and hindsight on the transition, the necessity to remodel the entire organization, and the coordination of data resources. Added to these challenges is the inequality between SMEs and MNCs in terms of resources, focus, and strategies in the transition to Industry 4.0. This section will present the three main difficulties faced by firms integrating Industry 4.0.

Lack of experience and established models

The lack of experience is certainly one of the biggest factors that hold back businesses from transitioning to Industry 4.0. era. Indeed, the transformation of the companies is very costly, and no clear business case is available as a reference for companies. It is very difficult to justify such investments when there is no perspective, no pattern to follow, and no successful case to reproduce. Therefore, most frequently, companies will either fail in their transition (60% rate of failure) or simply lack the necessary courage to follow through the process of radically changing their organization and investing as much time and resources.

To tackle this challenge effectively, some interesting research in the field has started to emerge, building the first tools to approach the transition. According to Bibby et al. [34], firms should begin by assessing the current level of Industry 4.0 maturity in their specific context or supply network. This analysis will help them determine their strengths and weaknesses and focus their improvement on the right area. Few academic research has been done so far in this area, and much research is done by consulting firms. As an example, in order to assess the industry maturity level of firms, two Industry 4.0 assessment models have been developed in 2016 by consulting firms, IMPULS management consulting GmbH (IMPULS) and PWC. While the PWC model helps companies self-assess their level of maturity based on various criteria, the IMPULS model is focused on delivering improvement advice based on the company’s preparation. More of these models are currently developing, showing that the challenge of the lack of experience will likely be overcome with time as Industry 4.0 spreads across the manufacturing world.

The cost of restructuring the firms

The transition to Industry 4.0 from a traditional organization requires the restructuring of the entire organization, as tasks are automated and decision-making processes are programmed. Every firm will adopt the Industry 4.0 system. We will have to create new business models and define a new strategy. Indeed, this transition requires rethinking the whole organization and processes, interconnecting departments, buying new equipment or modernizing the existing one, re-assigning roles to employees, recruiting new operators, and many other disruptions of their current model. These major changes have a great cost for any business on many levels: financially, of course, but also in terms of time. Therefore, firms have to be especially careful when investing in these transitions in order to not fail it’s the implementation of Industry 4.0.

Advanced coordination across the firms

Another challenge of the implementation of Industry 4.0 is how to connect all data efficiently. Industry 4.0 requires the cooperation of all organizational units, from manufacturing, R&D, and IT, to sales and finance departments. Sometimes the walls separating these departments are very hard to break, adding to the difficulty of the transition. But the coordination of functions is only part of the issue: Industry 4.0 requires the management of the large quantities of data generated by diverse sources in the company. For example, production data will have to be processed and coordinated along with data from customer information systems. Data Integration is, therefore, a very difficult task, and the firms need to have the necessary talent from data scientists that will be able to process and model this data.

Inequalities for SMEs compared to large firms

More than 98% of firms in the developed markets are considered SMEs, and they are increasingly participating in the global value chains and global trades of goods, services, and components. Introducing the new I4.0 paradigm may have varying levels of difficulty depending on the size and available resources of the targeted firms. Starting conditions between Small and Medium Enterprises (SMEs) and larger firms are obviously very different and bring different challenges. According to Matt et al. [43], SMEs need specific strategies to properly implement I4.0 into their business model.

Large companies will usually follow the higher maturity level in the technological domain faster and more easily than SMEs because of the resources. Indeed, they have more money, expertise, and time to invest in this project. As a consequence, I4.0 is spreading more quickly across large companies which are investing and working intensively on introducing and enabling the necessary technologies. SMEs, however, are lagging behind because they lack the financial and human resources to research the risks and potential of implementing I4.0. These difficulties further enlarge the gap between SMEs and large multinational companies. However, SMEs have an advantage over large companies, which have a much more complex organizational structure and production processes. Therefore, it is much easier to implement the necessary changes to the organization and culture of SMEs.

Human resources challenges

According to the study made by Glass et al. [44], across 176 SMEs and 71 large enterprises, numerous barriers to Industry 4.0 must be underlined across business processes and models. The most important challenges include, of course, the multiple issues which arise from Industry 4.0 strategy modeling and the growing need for highly skilled workers with specific know-how, particularly oriented in high technologies, smart engineering, automation, and digitalization competencies and expertise, etc.

We can easily understand that, beyond such technical and future-oriented subjects applying to industries, which are already developed in multiple kinds of business corporations, human resources remain a major challenge for the spread of Industry 4.0 concepts, methodologies, models, and tools. For instance, Mubarak and Petraite [45] have raised a fundamental HR component of Industry 4.0 implementation: The concept of digital trust. Digital trust is situated between trust and Industry 4.0 implementation and implies HR issues. We can identify major human resources issues related to Industry 4.0 as the followings:

The dangers of the technocentric approach

When digital trust refers to a new working environment where technology and Humans interact for the welfare of a company and to answer the stakeholder’s needs, a danger of this approach would be the growth of technocentric businesses. In fact, in this model, the stakeholders will give more confidence in technologies, artificial intelligence, and automation to run their business activities and corporations rather than human beings. Indeed, The Deloitte reports questioned the preparedness of HR in an era of Industry 4.0 and the global value chain. Among the 32% of firms that are ready to face technological challenges, only 12% are ready to face the challenges emanating from the Industry 4.0 ecosystem [46]. This statistic illustrates the new trends for companies to focus on efficiency with the highest technological implementation rather than hiring people and maintaining their position through retention policies.

Digital transformation: The increase of ISHR, ARP systems, and ERP

The information systems of human resources (ISHR) illustrate the Industry 4.0 impact on Human resource function. Indeed, the ISHR technologies permit to automate, standardize with the intervention of smart technologies, activities that belong to HR functions as the following ones: Administrative procedures, training, payrolls management, recruitment, talents management, or even career development of employees within a company [47, 48]. Different systems like automation of robotic processes (ARP) and enterprise resource planning (ERP) were conducted to rethink the HR function. Those different tendencies push HR workers to acquire new competencies geared towards smart technologies and which are transforming their workstations and are implying new risks. On the one hand, we can identify the complexity of adaptation to the rapid change of HR function but also the risks linked to the security of information systems and the possibility to lose sensitive data to the benefit of the competition. As a reminder, ISHR systems such as the one proposed by the SAP software can contain confidential data such as the wages, the positions, the personal data of each employee, their curriculum vitae, the annual reports, information posted on the different job board and the main partners of the company, etc.

The recruitment, retention, and attraction of new talents

The fourth revolution required a highly-skilled workforce to be implemented, developed, used, and maintained. As a result, a wide range of industries needs a certain level of cooperation between machines and workers. If Industry 4.0 implies this tendency, it also underlines the growing trend of Google, Apple, Facebook, Amazon, and Microsoft (GAFAM) to conquer traditional industries in which they have the necessary knowledge and capacities to become undisputable competitors in multiple fields [49]. As an example, we can remember the creation of the Google autonomous car, the collaboration between the Volkswagen group with Amazon web services to collect and analyze its industrial data and become a major global leader of the automotive industry, and even the collaboration between Apple and General Electric (GE) to create new applications for the internet of things (IoT) platforms that benefit to GE industries purposes thanks to IOS (exploitation system owned by Apple) opportunities. Industry 4.0 increases competition, in traditional industries and markets (but not only), which seems to be overwhelming regarding the fast spread of the fourth industrial revolution. To overcome these challenges, companies must recruit highly skilled workers, and implement continuous reskilling, learning, and training programs in their HR policies [44]. Besides, one of the major HR issues is constituted by the launch of retention practices which will reduce the diffusion of confidential business information and enhance efficiency and profitability by staying competitive at the same time. We can understand that the rise of highly skilled workers’ demand would create a danger if it is not associated with HR policies to enhance workforce abilities to work in a new smart and autonomous workplace.

The adaptation to change

One major issue to face urgently for HR functions is the resistance to change. According to Deloitte’s [50] report, 17% of their interviewees are ready to manage working environments composed of people, robots, and AI interacting together while 60–70% will fail because they do not manage the adaptation to change properly. Also, Dhanpat et al. [35] confirmed this problem. They have shown that some employees can be resistant to change by being afraid of losing their jobs and being replaced by machines. Bonekamp et al. [51] also agree on the fact that the introduction of Industry 4.0 led to the suppression of standardized tasks by smart and autonomous systems. As a consequence, strong pressure is put on HR managers who require highly skilled people, to train employees and manage to dismiss workers for whom tasks will be replaced by smart technologies to gain efficiency and competitiveness in the global market. In 2016, The World Economic Forum (WEF) already raised awareness by making an announcement before the opening of the Davos forum: around 5 million jobs in 5 years will be suppressed within 5 years in the main global economies [52]. It is necessary for the HR function globally to answer and react to the exponential expectations of the fourth industrial revolution by taking into account its effect on the global workforce demand and its impact on the global economy and competitiveness.

Big data challenges (storage, RGPD, societal challenge)

The fourth industrialization reveals new challenges in business activities such as the management of Bigdata and cybersecurity. Multiple obstacles to Industry 4.0 remain redundant: The constraints are numerous because the digitization of the industry poses formidable problems of standardization and cybersecurity [52].

Indeed, through their research, one of the major challenges implied by this concept in the working environment is the deployment of Big Data, which creates a growing need to provide a legal framework for the protection of personal data and private life. Among the different cyber issues reported in Industry 4.0, the Deloitte report [50] identifies the top 10 cyber threats and their major data protection concerns.

Indeed, if legal restrictions increase to manage big data challenges, the different issues persist. In terms of an international legal framework, the ISO norm ISO/IEC 27001 defines the data security management for sensitive subjects such as financial, intellectual proprietary, employees, or even data entrusted to another company in the context of business activities. This norm is also called “Management systems of Information security” [53]. In addition, the European Union has implemented the General Data Protection Regulation (GDPR) to mitigate different kinds of challenges affiliated with the management of Big Data. GDPR regulations refer to “imposing a legal framework on the processing of personal data” [54].

However, despite the willingness to build an international legal framework to reduce risk related to Big data cybersecurity, there is still a long way to go for a proper framework of Industry 4.0. For instance, the Deloitte report has shown that one out of four firms is not developing, implementing, or documenting the industrial cybersecurity (ICS) specific policies and procedures, and more than 33% of manufacturers have not performed any cyber risk assessments specifically focused on the ICS operating on their shop floors, resulting in a potentially significant risk to their operations [55].

In terms of internal management, other issues can arise when a company starts using big data analytics in order to grow. The challenges to take into account include the lack of proper understanding of big data, and therefore, proper usage of the latter; data growth issues, or, “what do I do with this much information?” because the collection of such an amount of data must be useful for something. But what, exactly? Another issue is the confusion when selecting a Big Data tool. There is an increasing number of tools available on the market for firms to have reports and data concerning their businesses. However, it is often not very precise and easy when one is not really aware of what is best for them. This last point brings us to another issue which is the lack of professional expertise in the field of Big Data. Indeed, more and more companies are recruiting professionals and experts in the field of data, such as data scientists, engineers, and analysts. These professions are rare, and as the demand and supply rule confirms, it is quite costly for a firm to recruit, though it is a must when expecting to grow, especially in our current globalized market.

Strategies of Industry 4.0 Implementations