How did you like that steak you had at the restaurant last weekend?

Did your toddler get that measles vaccine?

Do you love to wake up to the smell of fresh roses on the bedside table?

Meat, vaccines, freshly-cut flowers, and more have one thing in common – they all require refrigerated transport to get to you in unspoiled or usable condition. This is where the concept of cold chain management comes into play.

What is Cold Chain Management?

As the name says, the cold chain is a logistics management process for products that require the refrigerated temperatures that customers demand. It’s a process since it involves performing a chain of tasks to prepare, store, and transport products along the cold supply chain. Failure to keep cold chain products cold will render them unusable, which leads to a wastage of the products. When cold products go bad, both the shipper and their client lose money. “Maintaining optimal temperature ranges throughout the entire process is critical for ensuring that temperature-sensitive products remain in their desired state, and this is where a successful cold chain comes into play. For example, to preserve its shelf life, we must keep ice cream frozen. If temperatures rise above the sub-zero ranges, the product will lose its solid state, rendering it unusable.

Suppliers of food and pharmaceutical products heavily rely on the cold chain to ensure shipment doesn’t become compromised before they reach the market. They always want to streamline their cold chain management yet that may not be their forte. Fortunately, they can always turn to dedicated shipping companies to ensure timely and efficient delivery of their shipment to consumers. Outsourcing relieves food and pharmaceutical companies of the need to commit their resources to the management of their temperature-controlled supply chain. It also allows them to focus on the core of their business knowing that they have a reliable partner willing to maintain their cold chain and work around their schedule.

A cold chain is a supply chain that deals with perishable, temperature-sensitive goods (also called cool cargo) such as fresh produce, meat, dairy, seafood, chemicals, pharmaceuticals, flowers, wine, etc. To ensure the quality and integrity of perishable goods, we typically need to maintain a specific low-temperature range. This involves refrigerating certain groups of products, freezing others, and subjecting some to extreme conditions (also known as an ultralow chain or deep freeze). Failure to maintain the right temperature leads to product spoilage and, ultimately, financial losses. The aim of cold chain logistics is to handle and transport temperature-sensitive items securely from the manufacturer or supplier to the consumer through a set of activities.

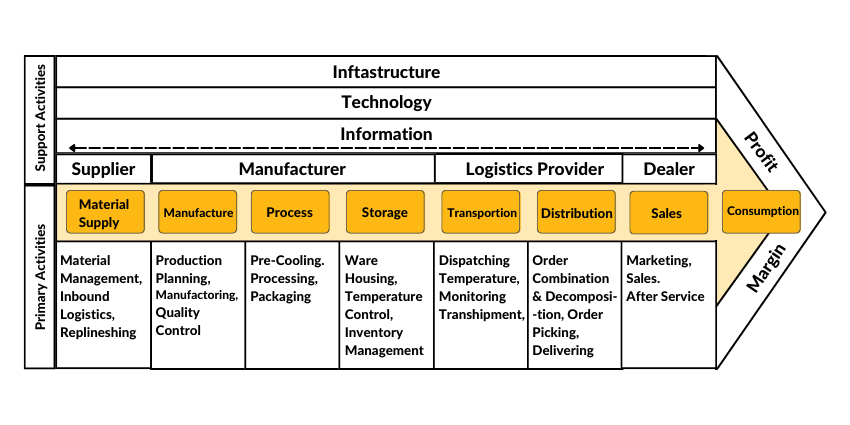

Cold chain logistics process:

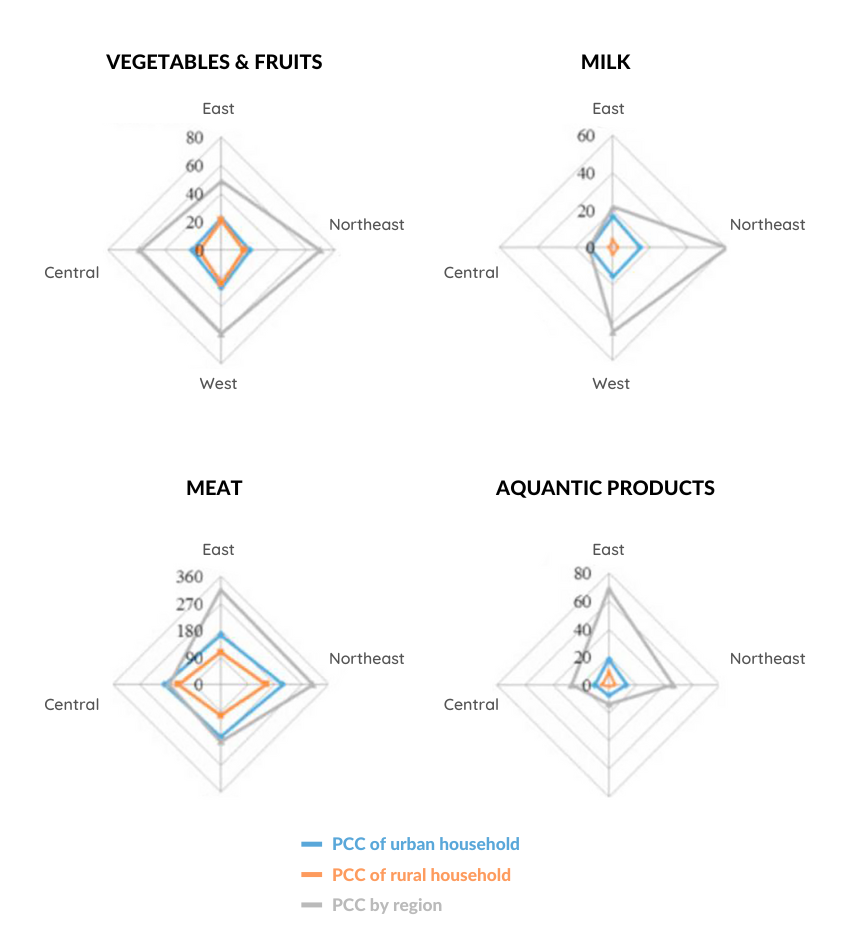

Overview of Cold-Chain markets and supply chain challenges:

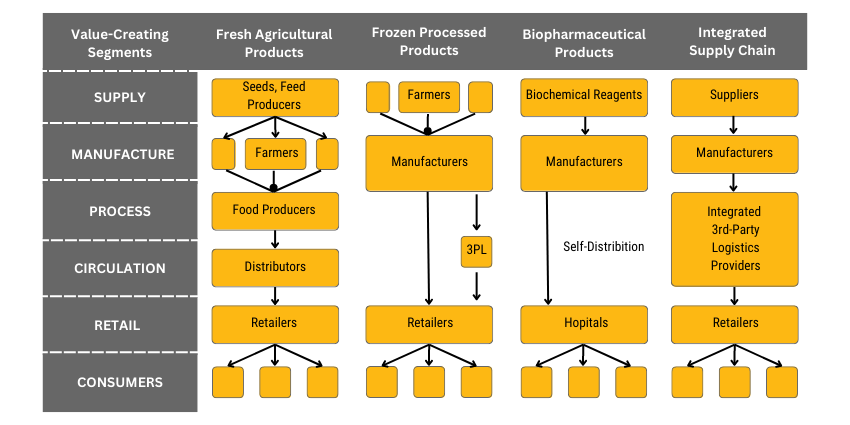

Categories of Cold Chain Products

| Category | Temperature Requirement | Product Specification |

| Fresh Agricultural Products | 0 – 20°C | Vegetables, Fruits, Meat, Poultry, Eggs, Aquatic Products, and Horticultural Products. |

| Frozen Processed Products | ~ – 18°C (< – 15°C ) | Frozen Foods, Poultry, and other Packaging Cooked Food; Ice-Cream and Dairy Products; Fast-Food RAW Materials |

| Biopharmaceutical Products | 2 – 8°C | Vaccines, Antibiotics, Biological Products, and Food Products. |

Value chain view of the Cold-Chain system:

Analysis of the supply chain structure:

Elements of the Cold Chain

Every link of the cold chain must keep temperature-sensitive products cold to ensure their quality and integrity. The chain has many components, including the following:

Storage

Contrary to popular belief, the cold chain doesn’t start when temperature-sensitive products leave a manufacturer’s premises. It starts with the storage of the products at a refrigerated facility. If manufacturers of cold chain products don’t have the storage equipment needed to keep their products cold, they’ll have to farm out their cold chain operations to a partner who can provide the equipment. Many 3PL companies offer warehouse facilities for the storage of cold chain products for some time, whether at an intermediary location for easy distribution to the local market or awaiting shipping to a distant market. Some common types of cold storage equipment and facilities include refrigerated containers, cold rooms, chillers, cold boxes, blast freezers, and vaccine carriers.

Packaging

Correct packaging is essential to maintain the quality of temperature-controlled products during shipment. Proper packaging helps minimize the risk of product contamination but also ensures energy-efficient storage of products along the cold chain.

Monitoring

Suppliers of cold chain products may need to keep track of specific types of information about their shipment, depending on the type of products they manufacture. This information includes temperature ranges and other environmental parameters, such as humidity levels that can compromise the integrity of temperature-sensitive cargo. Armed with this information, shippers can audit their supply chain processes to detect environments and activities that lead to inefficiencies.

Using data logging is a technology that can significantly simplify the management of the cold chain supply. This technology helps ensure efficient cold chain monitoring of temperature-sensitive goods. Data logging can improve quality assurance by enabling the identification and timely addressing of potential quality issues.

Data loggers can be wireless, standalone, web-based, or computer-based. Before making a final decision, one must carefully review the unique features, pros, and cons of each option. Consulting a service provider can help shippers identify the best data logging technology for their cold chain supply needs.

Transport

Cold transport involves the deployment of different transport solutions to move temperature-sensitive products from the point of storage to the consumer market. To transport cold chain products, companies use a variety of specialized transport vehicles and equipment, such as refrigerator vans, refrigerator trucks, and reefer containers. Companies can transport these products via road, rail, air, and/or sea.

Customs clearance

From a geographical viewpoint, the cold chain can be local, regional, or global. The cold chain is local when the point of harvest or production is close to the point of consumption. It’s regional when the point of production and point of use are in different regions of the same country. The cold chain becomes global when companies transport products overseas to reach consumers on the other side of the pond.

When it comes to the global cold chain supply, suppliers of temperature-sensitive products may need to obtain clearance from customs before they can deliver shipments to foreign jurisdictions. A specialized cold chain service provider can handle customs paperwork to reduce shipping delays that may arise from failure to meet all the relevant international shipping requirements.

Product handling

The cold chain involves moving temperature-controlled products along different points of the chain. This requires the use of material-handling equipment, such as shipping crates, boxes, and pallets, as well as conveyor belt systems. Without such equipment, shippers would take a lot of time to complete the delivery of cold chain products. This would make it difficult for them to make the fast deliveries needed to avoid loss of shipment.

Delivery

Cold chain management may also involve the delivery of shipment according to the end-user consumers’ preferred methods for receiving cold deliveries.

Top Trends in Cold Chain Management

The cold chain supply sector is constantly evolving to keep up with the needs of shippers and consumers. When people change their consumption patterns, suppliers of cold chain products have no choice but to adapt to meet the changing needs. These changes require companies to adapt their cold chain management operations accordingly. Some major trends in the cold chain management industry include the following:

Less than truckload (LTL) transportation

In a world where manufacturers of cold chain goods are always looking for ways to manage operating costs, LTL transport service is a welcome relief. With this new transport solution, companies that sell food and pharma products no longer have to pay for an entire trailer or full truck to deliver their shipment to the consumer market. All they need to do is to pay for the amount of space they use. To benefit from LTL shipping, businesses that supply cold chain products should ensure that they prepare their shipments for storage and transport. This will prevent carriers from having to spend resources handling incorrectly packaged cargo. They may also need to invest in transport management systems since many LTL shippers are slow technology adopters.

GPS technology

Businesses that deal in cold chain products want to keep tabs on the status of their shipment. They want to know that everything is going on as planned and that the shipment will reach its destination on time. Even with refrigeration systems in place, temperature-sensitive products don’t last forever. Hence, delays in the delivery of certain food and pharmaceutical products can lead to huge losses. Shipping companies heavily rely on GPS technology to keep track of their client’s cargo in real-time. This way, they can keep clients informed about the progress of their shipment.

Last mile delivery

The convenience of having orders delivered to their doorstep instead of having to go to local stores to get the products they want is worth paying extra for to many consumers. Freight companies are adapting to this need by offering last-mile delivery as an added service. In the context of supply chain management, people use the term “last mile” to refer to the final step of a product’s journey from the warehouse shelf to the consumer’s doorstep. The last mile process involves the direct delivery of cold chain products to end-user consumers, eliminating the need for retail intermediaries.

Importance of maintaining the cold chain correctly

The result of failing to maintain optimal temperatures at every step of the cold chain, even for short periods may lead to many undesirable outcomes. These include the following:

Product degradation

When cold chain shipment isn’t kept cold at every link of the chain, the quality of the shipment may be compromised, resulting in useless products. This may be tremendously detrimental in the case of shipping vaccines, pharma products, and essential food items.

Waste of suppliers’ money

When cold chain cargo goes bad because of failure to provide the consistent temperatures required for their preservation, shipment owners lose money. The extent of financial losses may depend on a range of factors including the type and quantity of products involved.

The financial impact of losses from a full truck of shipment is greater than a smaller LTL freight, for example. In a similar vein, high-value refrigerated products will lead to greater losses than cheaper products of the same truckload.

Deterioration of business partnerships

When shippers suffer heavy losses because of mistakes committed by their shipping partners, they’re bound to take legal action against them. They may also cut ties with their partners. This may result in legal battles that take time to resolve but also waste precious time and financial resources.

End-user consumer discontent

When cold chain products don’t reach the consumer market due to quality issues, consumers at the end of the supply chain are bound to become disgruntled. Empty shelves are no fun!

Why quality cold chain management is essential for vaccine supply

The ramifications of failing to maintain optimal temperatures for the medical supply chain supersede any business interests that shippers may have. That’s why it’s important to review the cold chain for medical supplies such as vaccines separately.

Failure to monitor vaccine temperatures properly may cause:

- Loss of potency – the formula will degrade and will need to be disposed of. Potency can’t be restored once it is lost.

- Waste of money – the manufacture and supply of vaccines involve a significant investment in research, product development, and distribution systems.

- Create a need to re-immunize patients – vaccines are essential to keep people healthy. When they become defective and unsafe, they’ll need to be re-manufactured to protect the population. Parties involved in the handling and distribution of vaccines must make sure the cold chain is correctly maintained to avoid the above risks. Every child matters – an effective cold chain helps deliver life-saving vaccines to every child in the world.

The importance of trained personnel in cold chain logistics

When talking about cold chain management, it’s easy to discuss processes, technologies, and equipment and overlook the important role that human resource plays in ensuring the efficient movement of products along the cold chain. For cold chain logistics to be successful, qualified staff must be used at every step of the process, including storage, packaging, condition monitoring, and transport.

Final word: Specialization is key to ensuring efficient cold chain management.

Not all temperature-sensitive products are created equal. Every product is unique and requires specialized handling to maintain its integrity along the cold chain. There are several regulations and guidelines that industry regulators set for shipping companies to follow throughout the cold chain supply. Beyond these guidelines, individual shippers must have in-house quality standards. The need to understand the industry, local, regional, global, and environmental regulations, as well as estimate the duration of freight accurately, is making many manufacturers of temperature-sensitive products outsource their cold chain supply to specialized shipping companies that can handle all their freight needs.

Cold Chain Logistics Management and Monitoring

Cold chains are a kind of supply chain that specializes in the storage, transport, and preservation of cargo that needs to be maintained at a specific temperature or within an acceptable temperature range.

Cold chains evolved due to a growing need for temperature-controlled logistics that could safely transport large quantities of food over great distances. Over time, however, cold chains have become an essential part of modern supply chain solutions to transport more sensitive or vital cargo over great distances through diverse climatic conditions.

Cold chains are vital in the storage and transport of the following products:

- Food & Beverages

- High-end foodstuffs

- Fruits & vegetables

- Meat & seafood

- Poultry & dairy

- Processed & ready-to-eat food

- Medical Goods

- Vaccines

- Pharmaceuticals & healthcare products

- Biologics (tissue samples, live cultures, etc., meant for medical research)

- Temperature-sensitive Chemicals

- Paint

- Volatile chemicals

- Other Temperature-sensitive Items

- Plants & flowers

- Synthetic products

- High-tech electronic/electrical components

- Photographic film

While an important part of cold chain logistics management is maintaining low temperatures to preserve perishable goods, not all cold chain cargo needs to be transported at sub-zero temperatures. In winter, for example, some fruits & vegetables need to be kept warm to preserve their texture or to ensure they last longer. Different cold chain cargo needs different temperatures and ambient conditions to be maintained, which is why cold chain logistics is also known as temperature-controlled transport or cool chain logistics.

Temperature standards for cold chain logistics

Temperature-controlled transport is generally categorized into the following temperature ranges:

- (-28 °C to -30 °C) Deep freeze — seafood, meat exports.

- (-16 °C to -20 °C) Frozen — meat, certain types of produce.

- (2 °C to 4 °C) Chill — fruit & vegetables, fresh meat, certain dairy products.

- (2 °C to 8 °C) Pharma — medicines, vaccines.

- (12 °C to 14 °C) Cool-chain — fresh produce, processed food, over-the-counter drugs.

Transporting goods at these temperature ranges would have been very difficult if not for the development of new techniques and technologies that help transporters achieve ideal temperature-controlled shipping conditions. Temperature-controlled transport options give modern businesses the flexibility and confidence to develop global supply chains for temperature-sensitive perishable goods.

Parts of a Cold Chain Logistics Operation

The cold chain has four main components, each of which must work flawlessly to ensure the safe transport and storage of cold chain products:

- Temperature-controlled storage — specialized refrigerated facilities where cold chain cargo is stored until it’s shipped out to a distribution center or its destination.

- Temperature-controlled transport — customized insulated cold containers that help transport goods via airways, waterways, roadways, or railways.

- Trained and diligent personnel — who are familiar with the complexities of handling sensitive cold chain cargo.

- Efficient operational and management procedures — to minimize risk during day-to-day operations as well as contain it in case of unexpected incidents.

Managing cold chain warehousing and distribution is usually outsourced to third-party logistics operators (3PLs).

3PLs offer logistics services that can be customized according to specific requirements as well as scaled to suit changing needs. Experience and expertise in cold chain management allow 3PLs to operate at costs lower than their customers would manage for themselves.

Cold chains differ from regular supply chains in terms of:

- Cargo sensitivity — cold chain shipments are quite sensitive to thermal stress, and tolerance levels are often just a few degrees.

- Logistics hardware — which is far more customized and tailored to specific product needs.

- Packaging — which is far more complex because it must insulate and contain sensitive products as well as volatile coolants.

- Costs — cold chains are far more expensive to manage, both in terms of operational overheads and in the event of a disruption.

- Cargo handling — which needs to be done with special care, in temperature-controlled environments.

- Regulatory compliance — which is far more stringent these days, and differs from region to region.

- Customs procedures — which are far more complex, especially when sensitive shipments of food or medicines are involved, or when they’re packaged using refrigerants that may be strictly regulated in some regions of the world.

- Operational complexities — cold chain logistics operations are significantly harder to manage due to factors like the nature of shipments, the potential for hardware/coolant failures, stringent regulatory and handling requirements, and so on.

The greater range that globalization demands from today’s logistics services are pushing the limits of both the packaging and the integrity of the modern temperature-controlled supply chain. Given the potential for cold chain disruptions, the probability and cost of rejected shipments are higher than ever before. The concept of managing temperature-sensitive products has been around for a long time, but the technologies in play have evolved tremendously over the past few decades.

Cold Chain Warehouse Storage Technologies

- Deep Freezer (DF)

- Walk-in Freezer (WIF)

- Walk-in-coolers (WIC)

Cold Chain Transit Storage Technologies

Reefers — specialized trucks or containers with active cooling through battery-powered or other forms of refrigeration; can be used to transport bulk cargo over the road, rail, or ocean.

Air freight containers — containers that are designed to fit the confines and compliance mandates for airline freight; usually used to transport smaller expedited cold chain shipments.

Ice Lined Refrigerators (ILR) — heavy-duty insulated containers that are lined with coolants; passive cooling that relies on its coolants to maintain low temperatures.

Cold Chain Cooling Technologies or Temperature Control Methods

- Passive Cooling

- Phase Change Materials (PCM).

- Evaporative cooling. Cooling agents like ice, dry ice, gel packs, liquid nitrogen, etc. as dunnage.

- Active Cooling

- Reefers — portable powered refrigeration units that run on fuel or battery packs.

- Absorption or compression refrigerators/freezers — preferred when a power supply isn’t available or reliable.

Cold Chain Packaging Technologies

- Insulators — thermal blankets, specialized foam, cold insulation bags, Vacuum Insulated Panels (VIP).

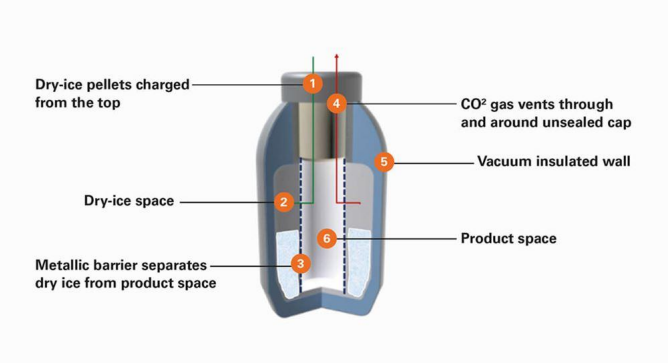

- “Dry” or “wet” shippers — a specially designed vessel with space for liquid nitrogen.

- Cryoboxes or polystyrene containers — special cold box or cool box containers that can be customized for specific cargo, usually Expanded Polystyrene (EPS) or Expanded Polyurethane (EPU) containers.

- Active containers — highly compact portable reefers.

- Key Elements of Cold Chain Passive Packaging Systems

- Rigid outer casing

- Vacuum-insulated thermal panels

- A temperature control medium or PCM

The cold chain is vital to improving global food security, supplying better nutrition and medicines to the remotest regions of the world, as well as furthering medical and scientific research through the reverse cold chain. Temperature-Controlled logistics also have an important role to play in modern-day business. Some of the advantages that effective cold chains give modern enterprises include:

- Reduced product spoilage — which leads to lower inventory replacement costs and more revenue per shipment.

- Lower likelihood of damaged products reaching customers — which means fewer legal and PR liabilities.

- Better product quality & consistency — which lead to better customer service and satisfaction.

- Greater range of transport — which helps boost exports and open new market opportunities.

- Better regulatory compliance — especially in the transport of food and medical products, must deal with more stringent norms that are being more strictly enforced across the world.

Efficient cold chain logistics are vital to franchisors and retail service providers who are eager to build global networks and take advantage of growth opportunities in emerging markets.

With over 70% of the world’s population residing in developing or emerging economies, there are huge business opportunities for companies willing to tap these emerging markets. Enterprising companies are keen to take advantage of modern temperature-controlled logistics that push the limits of what’s possible, transporting greater volumes of more sensitive goods over greater distances.

This same push, however, is also amplifying risks. Besides the usual elements of risk that plague normal supply chains, cold chain logistics has its own unique set of problems such as product sensitivity, the mounting cost of freight, and growing regulatory hurdles.

Risks in cold chain logistics

Some of the biggest risks in cold chain logistics include:

- Issues during transport — such as disruptions in electrical supply for reefers, coolant or container/equipment failure (which can get compounded due to a lack of fuel or spare parts), poor coolant circulation within containers, and exposure to the elements.

- Issues during warehouse storage — such as power outages, poor insulation, and non-uniform cooling.

- Incidents during handling — such as loading/unloading operations in areas where temperatures aren’t regulated, bad handling that damages packaging or the product, exposure during transfers, or last-mile delivery.

- Insufficient cold chain capacity/infrastructure — especially in geographies where cold storage facilities and other essential cold chain components aren’t adequate.

There are many more cold chain risks that could trip up temperature-controlled transport, out of which, the major pain points include:

- Higher Costs

- No uniform global practices to follow

- Customs, legal, and compliance issues

- Effects on the environment

- Supplier-related risks

- Issues with cold chain delivery — packaging, hardware issues, vehicle breakdown, etc.

- Chances of Human error

- Security risks

- Retailer Risks

- Consumer Demand Risk (Bullwhip Effect): The Bullwhip effect occurs when a change in consumer demand causes supply chain participants to order more goods in order to meet the demand thereof. When you’re dealing with a cold chain, the bullwhip effect can get even more complicated since the goods involved therein are more sensitive to issues caused by delays or disturbances of any kind. It affects the inventory at every level — ingredient manufacturer, parts manufacturer, module manufacturer, assembly, regional warehouses, stores, and so on, and gets more intense at each successive level, giving way to goods as well as pallet over-stalking, which is a real problem.

- Ultimately, the increased uncertainty causes lower forecast accuracy, which in turn contributes to unnecessarily high inventory volume.

- Globalization – and new market opportunities.

- Stricter Regulations — especially for food and medical shipments.

- Higher Product Sensitivity — especially for medical and high-end products that have a lower tolerance for temperature excursions.

- Availability of Better Technology — both for the storage and transport of temperature-sensitive goods.

- Cost Fluctuations — especially the rising cost of air freight. Better technology is enabling shippers to consider modes of transport like ocean liners or surface transport that wasn’t viable earlier due to issues with reliability. In an effort to reduce cold chain risks and improve operational efficiencies, enterprises, and 3PLs alike are stepping up their game in both cold chain risk assessment and management. While there may be some differences in opinions about the best strategy to reduce cold chain risks (and costs), the first step is usually a push for better cold chain visibility.

Cold Chain Risk Management

The biggest and most obvious risk to cold chain operations is temperature excursion, which leads to temperature-controlled transport’s biggest problem – product spoilage.

Processes, participants, external factors, poor management of resources, limited financial capacity, and shipment security — these are some of the weakest links in cold chain operations that inevitably result in temperature excursions, or worse.

The easiest way to identify (and subsequently reduce) risk is to spot problems before they have a chance to snowball.

That’s where tracking technologies come in.

Temperature tracking is the first step toward effective cold chain management. To minimize the chances of temperature spikes in transit, transporters used simple measures like risk assessment for standard routes to identify their safest option, using dedicated vehicles, using things like phase change gel bricks to identify excursions, or doubling up on packaging and active cooling to secure their shipments.

Newer technologies have given logistics players more options to track and manage their cold chain operations though. Some of the most common and effective temperature-tracking solutions for cold chains include:

- Infrared Thermometers: Allows a user to scan shipments from a distance and measure surface temperature.

- Wired Digital Thermometers: Sensors are placed in the cold storage area and hooked up to a monitor/logging device through wires. Usually used to monitor ‘deep freeze’ or ‘frozen’ shipments, where conventional temperature loggers can’t survive due to the extreme cold.

- Temperature Data Loggers: By far the most popular cold chain temperature tracking solution today, temperature data loggers are usually part of the cold chain shipment in transit. Temperature data loggers are commonly classified into the following types:

- Passive Temperature Loggers: Battery-powered devices simply log temperature data at set intervals, which can be downloaded for analysis through USB or other connectivity options.

- Wireless Temperature Loggers: RFID or Bluetooth temperature data sensors (also known as beacons) are similar to passive temperature data loggers. Their data can be accessed wirelessly, making it easier to use in large-scale operations.

While the data gathered by temperature loggers helps to detect temperature excursions and spoilage more reliably (perhaps even make improvements to overall efficiencies) they can’t really help reduce product spoilage. That’s because most logger reports are generated well after the temperature excursion occurs, which means there’s nothing that can be done about it.

Not all cold chain products spoil as soon as they cross their ideal storage temperature. Rather, it’s the ‘degree’ and ‘frequency’ of changes in temperature that determine whether they spoil. Although a temperature spike may not necessarily indicate spoilage, stringent norms for the secure transportation of food and medical products dictate that the entire consignment be discarded.

To reduce such unnecessary wastage in cold chain shipments, industry players are shifting to a different system — known as Mean Kinetic Temperature (MKT) — to better gauge the impact of inevitable temperature excursions in cold chain logistics on the health of their shipments.

Are cold chain drugs adequately inspected to prevent spoilage?

Technology has come a long way when it comes to tracking and tracing cold chain, but it is still in the process of getting where it needs to be when it comes to monitoring the cold chain, especially when dealing with pharmaceutical cold chain. More often than not, cold chain drugs get spoiled or damaged during transit, or at a facility for the lack of adequate inspection. In absence of optimal solutions to problems like temperature excursions, cross-contamination, and delays in delivery causing spoilage, the pharmaceutical cold chain suffers more than it can handle.

Although we have temperature loggers, and BLE beacons to take care of a lot of things going on in cold chains, what is actually required to perfect cold chain monitoring is — managing the MKT, real-time updates, actionable information about the supply chain, and predictive analytics to make the best use of the available data.

To overcome these limitations, transporters need more timely updates on the state of their shipments. This led to the development of newer ‘active’ temperature data loggers. Like passive and wireless loggers, they record temperature data. What sets them apart is the ability to connect to a communication network (like GSM or Wi-Fi) which allows them to transmit live data as well as instant alerts in case of temperature excursions. The ability to register temperature excursions in real time was a game-changer for risk management in cold chain operations. Temperature-Controlled logistics management switched from reactive to proactive, and transporters began to explore the advantages of data-driven decision-making.

The constant drive to improve efficiency (and cost-efficiency) pushed cold chain management toward solutions that leverage the advantages of constantly connected and communicating devices. Cold chain management, whether it realizes it or not, has taken its first definitive steps into the IoT age.

The need for more data to make better decisions has spurred further improvements to cold chain monitoring solutions, some of which include:

- Constant communication for real-time temperature updates and alerts.

- Additional data such as shipment location, its condition, and relevant external feeds like weather and local traffic conditions.

- Smaller, portable, energy-efficient monitoring devices that can be used for multi-modal shipments and can be managed remotely.

- Convenient reports, real-time dashboards, and better contextual information make cold chain monitoring and management easier.

- Cloud-based real-time predictive analytics to identify risk as well as opportunities to improve efficiency.

- Real-time contingency and crisis management that takes full advantage of live cold chain monitoring, staying one step ahead of any disruptions.

Learn the differences between temperature data loggers, Bluetooth temperature sensors, and IoT.

Cold chain risk management strategies are being upgraded to take advantage of these developments, leveraging the power of automation, machine learning, and predictive insights that such systems allow for. The hybrid combination of robust monitoring devices, constant connectivity, and analytics that enable data-driven improvements to cold chain logistics operations represents the pinnacle of cold chain monitoring and management systems.

Cold chain monitoring using IoT to reduce your supply chain cost.

Real-time intelligence is vital to monitor a temperature-controlled shipment’s condition, and route/carrier performance, as well as to stay one step ahead of the cold chain risks that could disrupt operations.

Understanding and optimizing cold chain performance is often constrained by a lack of effective visibility. While it’s possible to piece together a reasonably complete picture of cold chain performance through periodic reports, historical data analysis, or ad-hoc evaluations, you need systems in place that provide constant insight into cold chain performance and day-to-day operations.

The easiest and best solution to achieve that is through hybrid IoT cold chain monitoring systems that combine the best of two worlds – physical machines gathering real-time data that are streamed to virtual machines in order to generate real-time predictive analytics.

An ideal real-time cold chain monitoring solution should be set up as follows:

- Deploy sensors/monitoring devices to gather live temperature data.

- Ensure the devices also gather other contextually important data like location and condition.

- Monitor at the package level to reduce the risk of missing hotspots in cold chain storage or transport.

- Ensure constant connectivity to guarantee real-time temperature excursion or anomaly alerts.

- Fine-tune the data analytics and predictive algorithms, to ensure your smart system is firing on all cylinders.

- Make sure the reports, alerts, and overall system are easy to use for relevant stakeholders.

- Ensure there are contingencies and measures for rapid response in place to capitalize on predictive or real-time alerts.

- Make sure your monitoring hardware is reusable and easy to recover to maximize ROI.

- Make sure the monitoring system is pay-per-use or pay-as-you-go; ensure it’s scalable when required but flexible enough to accommodate fluctuating budgets.

Things That Can Go Wrong Despite Cold Chain Risk Management

A Cold Chain doesn’t have it easy. It needs to deal with all the usual things that trip up most supply chains AND then deal with its own unique set of problems — all without losing its cool. Yet, most of the things that can put your cold chain at risk can be bucketed into ten broad categories. Let us understand what they are and how you can get a handle on them.

Socio-political unrest, labor shortages, wars, geological events, to pandemic concerns; are just a few of the things that could affect changes in shipping patterns and/or logistics strategies. Seemingly unrelated events halfway around the world can impact a shipment out for delivery, and there’s nothing your production or logistics teams can do about it. That’s the inherent volatility of a supply chain. It’s worse still for temperature-controlled logistics. Therefore, the best you can do is mitigate the risk.

Shippers are urged to expect the worst and give their best when handling high-value shipments, ensuring there’s enough care and contingency in place to mitigate unexpected risks.

The problem is, supply chain risk management is a costly affair, and that’s especially true for a cold chain. Nonetheless, it’s a necessary cost to avoid unnecessary loss, especially when you weigh the strategic importance of cold chains to improve, nay, save lives. So, how can you reduce cold chain management risk while still managing your supply chain spending? It begins with understanding:

Shipping high-value consignments over long distances within their prescribed temperature range — consistently and without excursion — is a collaborative effort. Besides the usual suspects such as faulty hardware or human error, major unexpected incidents like worker strikes, pandemics, contamination scares, or anything leading up to acts of God really could cause a cold chain to falter. Cold chains could also get disrupted due to the following reasons.

1. Pressure to meet cost efficiencies in cold chain management

Despite the technological advances in cold chain technology, the most reliable solutions out there aren’t easily available because they’re simply too expensive. Most of the time, you or your transport provider are making do with what is “just enough.” This means the risk of failure of technology or equipment or the required amount of human effort in your cold chain is high.

2. Lack of uniform infrastructure globally affecting cold chains

It’s important to note that while scientific advances have led to more reliable cold chain technologies, even the most cutting-edge tech can stumble due to the lack of the little things. Even the most advanced and energy-efficient active cooling technology wouldn’t work without a power port to plug in, assuming of course you have the right adapter and voltage, to begin with.

3. Impact of increased regulations on cold chain management

Ecological

In addition to issues with high power consumption or the combustion of fossil fuels that are necessary to power active cooling systems, refrigerant gases such as Hydrofluorocarbons (HFCs) used in cold chains are responsible for high Greenhouse Gas (GHG) emissions, which don’t just hurt the environment, it creates compliance hurdles when you’re shipping across geographies. Different countries have diverse guidelines or mandates in place that govern the movement of cargo and its components.

Customs, legal, & compliance issues

Problems arise because there are no single global Good Distribution Practices (GDP), and even existing frameworks keep changing, adding to the complexities of compliance. Each region/country has its own regulations, compliance mandates, and levels of enforcement.

Globalization has made it vital for supply chain managers to stay up to date with regulations across countries, political or socio-economic developments that could affect their supply chains, as well as climate and weather patterns that could disrupt their logistics operations. It’s important not to underestimate the complexities of customs clearance. A lack of due diligence in documentation can result in clearance delays, or worse, inspections. Packages selected for customs inspections are often removed from controlled storage areas. That, coupled with the usual inspection regimes could compromise your consignment’s packaging, and ultimately, the integrity of your cold chain.

4. Environmental impact on your cold chain

While Mother Nature can be a hostile work environment for a supply chain or logistics professional, there are usually more tangible risks to contend with. Macroeconomic factors and fluctuations, environmental policy, regulation, and a number of other variables — global, local, sometimes even geological — can affect the supply chain’s business or operating environment, forcing logistics players to reevaluate or update their technology, practices, or contingencies based on strategic objectives.

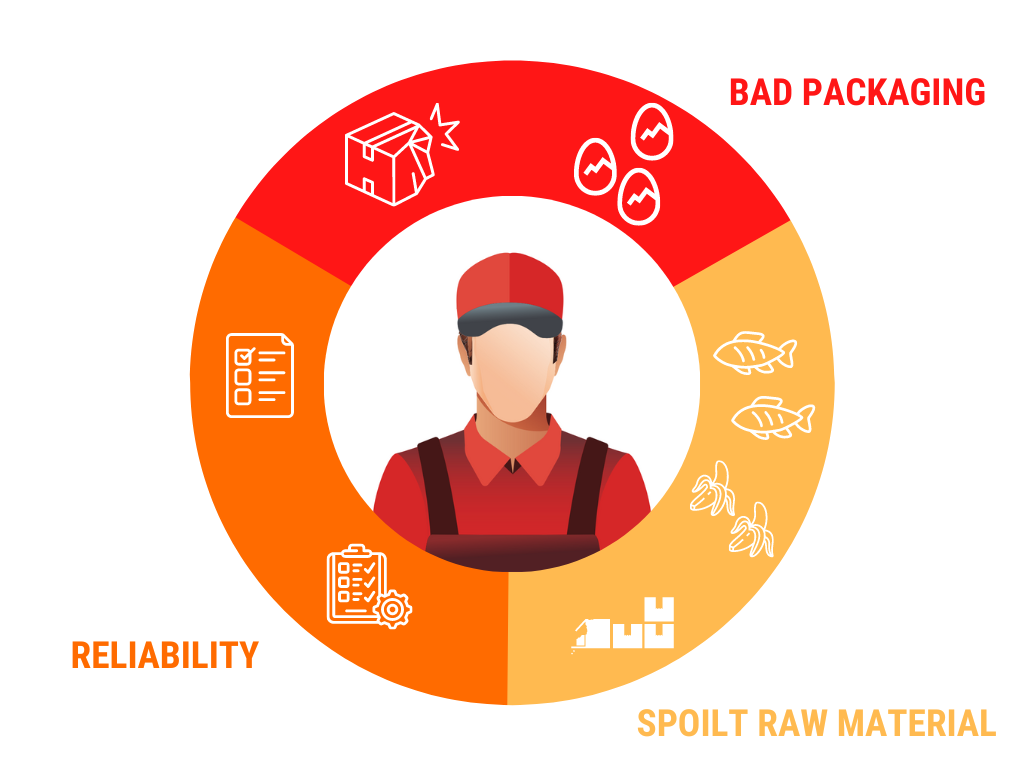

Plenty of things could go wrong before your refrigerated shipment has even begun its journey. They could include things like:

Bad quality or spoilt raw materials to begin with — especially in the food and fresh produce space, where damaged goods are packaged before they’re tested for quality or spoilage.

Dodgy relationships with suppliers — which could lead to less-than-ideal handling of your goods. Even with air-tight SLAs in place, you’d have a hard time knowing whether they’re adhered to, much less be able to enforce them.

Bad packaging practices — The packing process at the origin of the shipment needs to be performed in a temperature-controlled environment to avoid temperature excursions at the earliest stage of the transport chain. With the right packaging and shipment conditioning from the start, it’s easier to prevent temperature excursions.

5. Distribution/Delivery risk in cold chain

The distribution process is composed of two different activities: transport and storage.

While the storage aspect of cold chain management is usually nailed down pretty tight, temperature management in logistics and transportation isn’t as foolproof. It’s ironic really; after all, transportation in the cold chain logistics industry is just a mobile form of storage — with many more variables to deal with, of course.

There’s plenty that could go wrong, starting with:

- Packaging-Failure-Icon. Packaging Failure — Especially when packaging isn’t done correctly, or it gets damaged during transport or handling.

- Cold Chain Hardware Risk. Hardware Failure — This could include breakdowns in cooling solutions for active cold chains such as refrigeration equipment failing due to malfunctions, inadequate maintenance, or simply losing power.

- Cold Chain Vehicle Breakdown. Vehicle or Modal Breakdown — A vehicle breakdown in cold chains means more than just a delayed shipment, it could mean a destroyed one — whether it’s on a vehicle, plane, or ship.

- Cold Chain Risk-Lack-of-Equipment. Lack of Equipment — This is a particularly difficult issue to contend with. While you may invest heavily in the latest technology to ensure your cold chain’s integrity, any breakdown in the field will almost certainly spell disaster if you don’t have the expertise or spare parts handy to fix it. Cost and environmental concerns are also pushing supply chains to reevaluate their transport modes, and unfortunately, despite the risks and what’s at stake, cold chains can’t afford to be indifferent to these concerns. Not many ports or airports around the world have reliable temperature-controlled storage areas. Even when present, they may operate at fixed temperatures that may not be ideal for your consignment, assuming, of course, that they’re well-maintained and running at all. Even with the improving quality and availability of refrigerated transport for long-haul modes of transport such as reefers, refrigerated trucks, reefer containers, and temperature-controlled ports & airports, a number of different factors from the failure of packaging, processes, hardware, or the mode of transport itself challenges the cold chain when it comes to maintaining temperatures over longer supply routes.

6. The human element in cold chain risk management

While new cold chain technologies and techniques, whether it’s related to packaging, handling, or transport of the temperature-controlled shipment, do go a long way toward improving cold chain efficiency and security, they can all fail if the person handling your goods isn’t using it properly.

Training and management of human resources are critical to achieving effective distribution.

Language barriers, insufficient communication, and a lack of motivation can hit worker performance. In addition, careless staff, a lack of proper training or adherence to proper procedures, and ineffective use of equipment are what bring most cold chains down.

Some of the most common “human error” horror stories involve:

- Bad or High-touch Handling: Food is constantly moved in and out of temperature-controlled zones throughout the cold chain before it’s actually consumed. These points of transfer — between warehouse and truck, between truck and ship/airplane/ship and back, between truck and refrigerator — are among the weakest links in a cold chain, since they’re handled by humans, and susceptible to human error. Even a small variation or deviation of temperature for a short time can damage or decrease the shelf life and quality of cold chain products like food or vaccines significantly.

- Bad Handling Environment for Temperature-controlled Shipments: This happens especially during pickup and delivery. Incidents of damage or spoilage of temperature-controlled products usually occur when they’re loaded into refrigerated packaging or unloaded at their point of delivery. Incidents also happen when there’s no emphasis on proper preconditioning of the packaging system, handling temperature-sensitive products in a temperature-controlled zone, use of proper/professional equipment, or proper training of the handling staff.

- Lack of Proper Training: It leads to incidents, like turning the air-conditioner (AC) off in refrigerated transport because it’s passing through a frigidly cold area. It may seem like a good idea to save on power or fuel, but if that container is carting fresh produce, the whole shipment could be lost due to frost. Training-related issues largely occur when contract staff is hired or third parties are used in a cold chain. A cold chain isn’t about keeping things cold, it’s about

- Temperature control: Fresh vegetables and fruits don’t do so well in sub-zero temperatures for long. They need to be transported in heated containers during winter so they last longer.

- Lack of SOP/SLA Adherence and Enforcement: You could have the best training programs and SLAs in place, but unless you’ve got reliable ways to track whether your handling instructions are followed during your absence, they’re just a waste of toner.

- Lack of Preparedness: Your goods could get contaminated when things like rerouting options or sources of coolants en route to replenish failing packaging for at-risk shipments aren’t prepared beforehand, once again putting your cold chain at risk.

7. Security risk in your cold chain

Security for temperature-controlled products — like pharmaceutical drugs or controlled substances — is more important than for ambient goods. Think of a temperature-sensitive vaccine re-entering the supply chain after being stolen. The lack of effective security measures could affect your supply chain’s integrity and audibility, increasing the likelihood of damage — damage that you would never know about. The ultimate cost of such compromised food or tainted drugs re-entering the supply chain — and the danger to human life — cannot be quantified.

8. Retailer risk in your cold chain

If a cold chain breaks down after delivery, whose problem is it? Besides human handling during the delivery process, the way retailers handle and store cold chain products like food or vaccines, how their staff approaches the preservation and safety of products, as well as the measures they take to reduce spoilage, everything ultimately affects quality. The lack of understanding about cold chain best practices can create risks for the quality of cold chain products, and the lack of visibility at the store level creates a blind spot for manufacturers with regard to their cold chain’s integrity from manufacturing to point-of-sale.

9. Customer/Demand risks to your cold chain logistics

A stable but slow-moving supply chain will find it hard to cope with the volatility created due to sudden changes in consumer demand. It’s difficult, for instance, to reroute a consignment of meat or produce that’s heading to an area where demand dropped because there are pandemic or contamination scares. This can lead to wastage and financial impact unless the cold chain integrity of the goods is traceable and you know which item was exposed. Apart from the financial impact, supply chain risks due to weak links in a cold chain can cause product quality concerns, resulting in significant losses due to producing spoilage in transit, which could also lead to more dire consequences such as loss of market share, or worse, loss of life. Therefore, it is important for you to assess your operations in order to reduce, if not outright eliminate, these risks in cold chain logistics.

How to Reduce Risks in Cold Chain Management

It’s no secret that cold chain assurance will cost you, but how can you run a lean cold chain while still mitigating the risks?

- The key to dealing with unforeseen challenges is to prepare, plan ahead, and have enough contingencies, as well as a robust risk management strategy in place, supported by stringent processes and technologies.

- How can you achieve that when the window to act and prevent losses can be a matter of hours or scant minutes?

- You need a real-time cold chain monitoring system that can monitor your temperature-controlled shipments in transit as well as in a warehouse.

- Temperature data loggers only provide you with post-shipment audit trails, but with the number of weak links in your cold chain, you would need more actionable real-time data.

- Through such real-time location and condition monitoring solutions, you can:

- Track the shipment’s location and condition – key to knowing what is happening, where, and when

- Monitor details in addition to more than temperatures, such as humidity which is critical for certain types of vaccines and perishables

- Analyze patterns and predict if something is going to go wrong in the future

- Take preventive measures promptly using a control tower, and initiate corrective action before the shipment is destroyed.

- Contain risks, especially

- Safety – such as recalling compromised products before they hit customers

- Financial – such as recalling compromised products rather than the complete batch

- With real-time location and condition monitoring solutions like Roambee, you can make the right decision – whether it’s to deploy personnel to fix a cold chain issue, re-route your shipment, or re-ship a replacement so your customer is not affected.

Cold Chain Logistics Use Cases

Multiple industries, including agriculture, manufacturing, and healthcare, strongly rely on cold chain logistics to safely store and transport perishables. Today, the need for such services keeps increasing due to changing consumer demand, trends like “from farm to fork,” and the necessity for new drugs and vaccines. Let’s look closer at industry sectors that need cold chains the most.

Cold chain in the food industry

Storing and transporting perishable food products is the oldest and most obvious cold chain use case, originating centuries ago to avoid rot or mold. We all know from our middle school (and our own experience) that the quality of certain food categories degrades with time because of natural chemical reactions – reactions that can be slowed down with lower temperatures.

There are several categories of food that require different thermal conditions.

- Banana: Tropical fruits like bananas or pineapples undergo controlled ripening as they are transported, so they need a stable range of 12° to 14°C (53° to 57°F).

- Chill: Most vegetables, fruits, dairy products, and meat must be refrigerated around 2° to 4°C (35° to 39°F).

- Frozen: Meats, bread, cakes, and most other products that need freezing require temperatures between -10° and -20°C (14° to -4°F).

- Deep-frozen: Seafood, ice cream, and some other items have to be deep-frozen or stay between -25° to -30°C (-13° to -22°F).

Cold chain in pharmaceutics

The demand for cold chain logistics services in pharma has grown steadily over the last few years. The 2020 Biopharma Cold Chain Sourcebook predicts that this market will be worth $21.3 billion by 2024 (up from 2019’s $15.7 billion). Blood, stem cells, tissues, transplant organs, as well as diverse drugs and vaccines – all these items need a range of 2° to 8°C and sometimes down to -80°C. If the required temperature level is not maintained, such products can become useless or even harmful to patients.

Recently, billions of COVID-19 vaccines had to be spread out on a global scale – and they require a stable, ultra-low temperature of below -70°C (so do some others, including the Ebola vaccine). Besides, a large number of new drugs being approved by the US Food and Drug Administration are temperature-sensitive as well. So, the need to develop proper cold chain infrastructure to maintain required conditions at all stages is higher than ever.

Typically, if pharma goods have to be shipped urgently, they are transported by air. However, if time is not critical, ocean transportation is preferred because it’s cheaper and safer (i.e., less subject to temperature breaches).

Cold Chain Equipment and Packaging Options

We’ve already indicated that usually reefer trailers, diverse containers, and even specialized vessels are used to transport temperature-sensitive products. Liquefied gasses (such as oxygen, nitrogen, argon, CO2, etc.) are stored and transported in special cryogenic tanks, trailers, and railcars.

Meanwhile, for storage purposes, warehouse/terminal facilities and distribution centers are equipped with capacious walk-in coolers and refrigerators that maintain a stable temperature. To store pharmaceuticals, drugs, tissue samples, and other medical items, there’s a wide variety of laboratory refrigerators and freezers capable of supporting the required temperature.

As for packaging, there’s a huge range of cooling products to keep perishables cold. There are two main categories of such technologies.

- Passive cold containers rely on dry ice, gel packs, gel bottles, liquid nitrogen, eutectic plates, quilts, and other cooling/auxiliary stuff to keep the internal temperature low. Pharma products can be more demanding and require ultra-low freezing, so specialized containers are being developed to satisfy industry needs.

- Active cool containers can monitor and control the internal temperature level. Such powered refrigeration units include sensors, a control unit, and ventilators that adjust the temperature automatically to keep it stable. Comparing the two, active containers seem pricey at first, but they often turn out to offer more cost savings than traditional passive ones. They are reusable, take less space, require less handling, don’t need cooling material replacing, provide better-guaranteed temperature control, and can be shipped with other cargo or as LTL freight (which is cheaper than hiring dedicated reefers).

In addition, active containers include a monitoring device that provides an opportunity to track shipments and related activities. Let’s look deeper into which technologies make it possible.

Cold Chain Digital Technology

We’ve already mentioned the importance of complete visibility in cold chain logistics. Most temperature-sensitive products are also time-sensitive, and despite proper storage conditions, they have to be transported without delays. So, all stakeholders want to track such vulnerable cargo and constantly monitor its condition not only to be aware of what’s going on but also to be able to react quickly in case of any deviations. And that’s what modern digital technology can help with.

Tracking

For tracking purposes, you can take advantage of such technologies as:

- Global positioning system (GPS),

- Global system for mobile communication (GSM),

- Radio-frequency identification (RFID), and

- Bluetooth low energy (BLE).

If cold cargo is hauled by truck, telematics solutions powered by GSM/GPS allow for tracking the vehicle’s position in real-time while en route. Typically, location data is sent to the carrier’s transportation management system (TMS) or other business solution in use. Many carriers, in turn, provide their customers with access to tracking information via customer portals, or, at least, a link to the third-party tracking service provider.

Attaching battery-powered GPS devices to the shipping containers makes it possible to track their location whether they are transported by trucks, rail, or ships. Typically, cold chains prefer the ones that also have a monitoring functionality – we’ll talk about it in the next section. Data from such trackers gets to the carrier’s or shipper’s business management solution.

As for maritime shipping, major ocean carriers provide their vessels’ satellite location data through their websites/apps/customer portals, as do 3PLs and freight forwarders that deal with international shipping.

There are also a number of independent global sea data providers such as MarineTraffic that show real-time vessel positions. Whichever way you choose, nowadays it’s fairly easy to sit back and watch how your cargo is being moved around the globe.

RFID and BLE work in different ways. Tags or beacons have to be attached to containers or individual packages and scanned to fetch data. We’ve all seen anti-theft alarm systems in stores – that’s how RFID works.

RFID tags can be passive or active. The reader activates passive tags since they don’t have a power source. Active tags, having an inbuilt battery, can broadcast their own signal, making them scannable from a greater distance. However, they are larger in size and considerably more expensive.

RFID and BLE readers are usually installed at checkpoints (e.g., at terminals or distribution centers) so that they automatically scan all the tags/beacons within their working range. There are also handheld RFID readers, while BLE beacons can be scanned with a smartphone (which is their big advantage as it’s really cheaper). The data is then sent to the ERP, terminal operating system, warehouse management system (WMS), or other integrated business solution.

Please see the brief comparison of main tracking technologies in the table below. To sum it all up, GPS devices are perfect for real-time global/outdoor container or equipment tracking (but they are very costly and have shorter battery life), while RFID/BLE technologies work best for indoor use and receive periodic information on individual packages.

| GPS | RFID | BLE | |

| Price of Tag | $10 – $100 | Passive: Less than $1 Active: $20 – $100 | $10 – $30 |

| Size of Tag | 5 – 100mm | Passive: Less than 1mm Active: 5 – 30mm | 5 – 30mm |

| Price of Reader | Transmit Over Cellular Network | $100 – $750 Handheld: $500 – $4000 | Up to $100 Or a Smartphone |

| Read Range | Global | Passive: Up to 10m Active: Up to 100m | Up to 70m |

| Auto Scanning | ✓ | ✓ | ✓ |

| Best For | Outdoor Tracking of Vehicles/Containers | Indoor Tracking of Individual Shipments | Indoor Tracking of Individual Shipments |

Monitoring

The GPS and RFID technologies we described above work great for tracking purposes, but they can’t do measurements, store records, and transmit them. To monitor temperature, humidity, and sometimes even vibration, other types of devices are used in cold chain logistics, helping stakeholders ensure a safe and stable environment. Here are some of them.

Data loggers are the most typical monitoring solution. These devices are placed inside the container (or storage area) to measure temperature (and sometimes humidity as well) at regular intervals. They keep records of shipping/storage conditions that can be extracted by physically connecting to a data logger.

It’s a cost-effective solution, but its drawbacks are obvious: no real-time monitoring and the need to be in close proximity to retrieve data.

Bluetooth temperature sensors (that’s the same BLE technology we mentioned above) are more advanced as they can also add location data to temperature measurements and transmit records wirelessly when scanned with a reader or a smartphone.

However, they still don’t provide real-time monitoring by themselves. To receive live updates, they have to be connected to an IoT infrastructure.

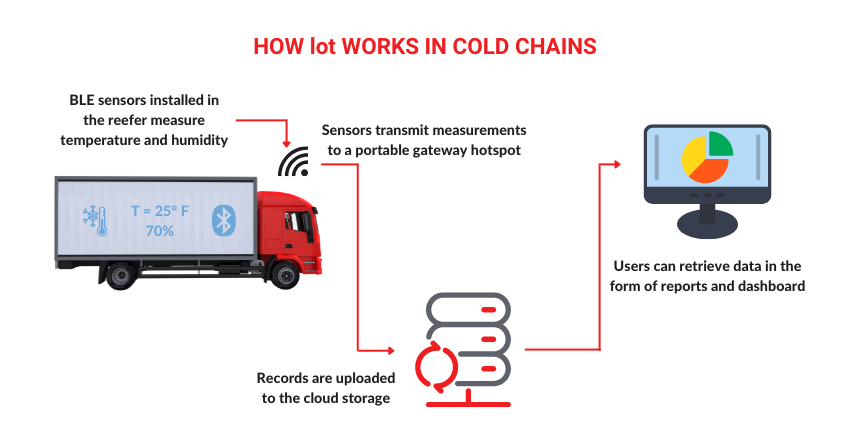

IoT is all about connectivity and real-time data (well, in our case it’s almost real-time; usually, measurements are made every few minutes).

A typical IoT infrastructure for cold chains includes:

- BLE sensors that are attached to containers, packages, or pallets and that measure temperature and sometimes humidity, CO2 level, and so on;

- A portable gateway hotspot that collects measurements from the sensors and transmits records to the virtual storage;

- Cloud storage that receives records, stores them, processes them, and allows for retrieving data when needed; and

- A user-facing app or platform (e.g., ERP, TMS, WMS, other business solutions, or specialized software) that visualizes information for users via dashboards and reports.

Such smart systems not only enable real-time monitoring but can also be configured to send alerts in case of temperature breaches or other abnormal events.

Integrating tracking and monitoring solutions

If you have just a few shipments in your cold chain, you can track them through a customer portal provided by a carrier. However, if you operate multiple shipments regularly, you need a more convenient way to track your cold cargo and ensure it’s safe.

As we said, you can install your own GPS tracking devices or design an entire IoT infrastructure to monitor all important indicators. But if you rely on the carrier to handle these activities, consider building an integration between your systems. It takes development effort, time, and investment, but the rewards are convenience and saved time.

As you establish such an API connection, you’ll be able to receive location, temperature, and other important information from the carrier/3PL right to your internal system. That will allow you to monitor the status of your shipments and timely react in case of disruptions.

Cold Chain Standards and Regulations

Since cold chains deal with very delicate and sometimes vitally important goods, there are multiple regulations and requirements set by various government institutions to ensure safe storage and shipping. Standards are established in relation to temperatures, timing, packaging, supporting documentation, and much more. We’ll only list the main regulators.

- The US Food and Drug Administration (FDA) develops standards that cover the entire supply chain from production to packaging to storage to last-mile delivery to documentation.

- In Europe, the Good Distribution Practice (GDP) is a main set of standards that all distributors of medicinal products must comply with.

- The World Health Organization (WHO) created Guidelines on the international packaging and shipping of vaccines to regulate pharma cold chains.

- The International Air Transport Organization (IATA) issued Perishable Cargo Regulations that contain guidelines on shipping sensitive products.

Additionally, IATA’s Temperature Control Regulations (TCR) were set apart as a standalone publication to ensure the safe air shipping of pharmaceuticals. TCR requires special Time and Temperature Sensitive Labels to be used. Also, since 2013, aircraft operators and ground-handling agents must verify their compliance according to IATA’s Standard Acceptance Checklist.

Other regulating bodies like the European Parliament, US Customs, the Transportation Security Administration (TSA), and the Department of Transportation (DOT) also have their requirements, but they concern usual supply chains as well. Besides that, each country has its own regulations.

Worth mentioning separately is the Global Cold Chain Alliance (GCCA). GCCA unites 1,100 cold chain logistics service providers in 85 countries and its mission is to build a universally strong and safe cold chain. Together with its core partners, GCCA develops best practices and guidelines, provides advisory services to governments and organizations, conducts assessments and research, and serves as a universal voice of the cold chain industry.

Cold chain logistics companies

Both shippers and 3PLs/carriers encounter lots of complexities at each stage of the cold chain process. So, it’s not uncommon to outsource at least part of the job to third-party cold service providers.

Shippers can definitely use the services of such major carriers as FedEx or UPS to transport their perishables, but specialized companies have developed a niche logistical expertise that allows them to professionally handle temperature-sensitive products for their clients. But where to find a reliable partner?

For that, we can turn to the global top-25 list, published annually by the International Association of Refrigerated Warehouses (IARW). These are the top three refrigerated warehousing and logistics providers as of March 2022.

- Lineage Logistics is an undisputed, permanent global leader of the food cold chain providers with a capacity of 2.6 billion sq. ft. (73.5 million sq. m.). It operates a network of over 400 facilities in 19 countries and is known for its tech innovations (see its Lineage Link supply chain management platform) and sustainable approach.

- Americold Logistics, founded in 1903, has a capacity of 1.4 billion sq. ft. (40 million sq. m.) and 250 facilities. It also provides transportation and warehousing services as well as technology solutions (check its i-3PL supply chain control system).

- United States Cold Storage, whose capacity is 423 million sq. ft. (12 million sq. m.) in over 40 facilities, is the third-largest provider of warehousing, transportation, and other logistics services.

As you may have noticed, these companies specialize in food cold chain logistics. To ship pharmaceuticals, it might be worth cooperating with such niche specialists as Envirotainer, PCI Pharma Services, or BL Turkey.

Cold chain logistics challenges

Shippers are ready to pay for secure cold storage and transportation to prolong the product’s shelf life and satisfy customer demand. However, carriers and 3PL companies face multiple challenges that make cold chains a tough business.

Creating and maintaining infrastructure: The 26th Annual Third-Party Logistics Study released in September 2021 revealed that the majority of 3PLs reported investing in a cold chain infrastructure and maintaining it, and temperature monitoring as their main issues. To meet shippers’ requirements, 3PLs are forced to have a range of different equipment from coolers to deep-freezers, and invest in new technologies.

Proper handling: According to the same study, proper handling was the biggest challenge for shippers. To ensure product quality, certain sanitation, packaging, cleaning, sorting, and other practices have to be implemented.

Regulatory compliance: Multiple regulations keep all supply chain participants on their toes and make them invest in modernization to comply, especially in the aspects of goods traceability and visibility. Plus, temperature records have to be documented and stored correctly.

Other industry problems range from insufficient specialists to high spending on electricity. But despite all the issues, 91 percent of shippers and all 3PLs who took part in the research expect an increase in demand for cold chain capacity over the next three years. Intelligent businesses realize the importance of modernization and investment since it’s already clear that the future of cold chains is behind innovative technologies.

Danish Mairaj is a medical device expert with a strong focus on regulatory and quality compliance. He has been involved in managing clinical trial infrastructure including supplies and logistics. He has over 15 years of experience in the MedTech and Pharmaceutical industry. He is a certified Product Owner, Scrum Master, and Project Management Professional PMP. He studied Biomedical Engineering in Germany and MedTech Regulatory & Quality in Galway, Ireland. He contributes articles to the BRASI newsletter.

-

Danish Mairaj#molongui-disabled-linkNovember 1, 2022

Comment (1)

Natalie Stamey April 17, 2024

Hey, I’m Natalie from Social Buzzzy here. I’ve come across a revolutionary tool for Instagram engagement and had to share it with you!

Social Growth Engine offers an incredible tool that boosts Instagram engagement. It’s simple:

– Just focus on making amazing content.

– Affordable at just below $36/month.

– Secure, powerful, and perfect for Instagram.

I’ve seen fantastic results, and I believe you will too! Elevate your Instagram game now: http://get.socialbuzzzy.com/instagram_booster

Best wishes your success,

ReplyNatalie